IH_4_Me

Member

Hey guys,

Just a few querys about the International Harvester hydraulic system.

Question Part 1:

What type is it, is it different from other makes?

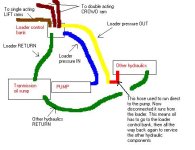

I ask this because my tractor (IH 574) has 3 hyd hoses running to the FEL control bank, whereas the tractor we have at work (JD 1640) has only 2, a pressure one and a return one, a very simple system. Both FEL's are identical but for the control bank. What is the reason for an extra hose on the Inter? The only reason I can think of is that it has a different hydraulic system than the John Deere.

Question Part 2:

Is there a way I can convert it to only having 2 hoses? Also, when I take the loader off, the tractor makes a whining noise from somewhere under the seat, exactly like the noise it makes when you extend a hyd ram to its full stroke and it won't go any further. Any ideas?

Thanks for your help as these things are bugging me! /forums/images/graemlins/smile.gif

Just a few querys about the International Harvester hydraulic system.

Question Part 1:

What type is it, is it different from other makes?

I ask this because my tractor (IH 574) has 3 hyd hoses running to the FEL control bank, whereas the tractor we have at work (JD 1640) has only 2, a pressure one and a return one, a very simple system. Both FEL's are identical but for the control bank. What is the reason for an extra hose on the Inter? The only reason I can think of is that it has a different hydraulic system than the John Deere.

Question Part 2:

Is there a way I can convert it to only having 2 hoses? Also, when I take the loader off, the tractor makes a whining noise from somewhere under the seat, exactly like the noise it makes when you extend a hyd ram to its full stroke and it won't go any further. Any ideas?

Thanks for your help as these things are bugging me! /forums/images/graemlins/smile.gif