Wild Bill the 2nd

Gold Member

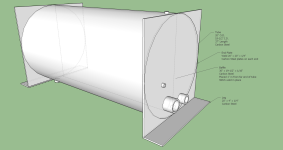

Changed the tank design. We used the domed lids on our fuel tank.

We are going to use some 20" pipe and weld on some flat plate at the ends. The tank will have a divider running down the middle as before but it will be flush to one end of the pipe and have a 1" gap at the far end. The 1-1/2" return line will enter on one side of the plate and the 2" suction will leave on the other. Fluid will therefore have to run the whole length of the pipe and come back up the other side.

I would think that any air bubbles should rise in that distance. Any concerns with that layout?

We are going to use some 20" pipe and weld on some flat plate at the ends. The tank will have a divider running down the middle as before but it will be flush to one end of the pipe and have a 1" gap at the far end. The 1-1/2" return line will enter on one side of the plate and the 2" suction will leave on the other. Fluid will therefore have to run the whole length of the pipe and come back up the other side.

I would think that any air bubbles should rise in that distance. Any concerns with that layout?