LD1

Epic Contributor

LD, I think it was you that showed the math on grapple "lid" closing pressure. Is there a big swing in capacity of a loader through out it's motion if any? Beyond the load's position in distance from the loaders point of rotation, it's force will remain the same correct?

No there is a big swing.

Remember cylinder on an angle thing.

The higher you raise the loader, the more acute the angle becomes.

Thats why you see many loaders give a rating for lift force at ground level, (sometimes called breakout force), some will give a midpoint capacity (usually at 59"), then a lift to max height.

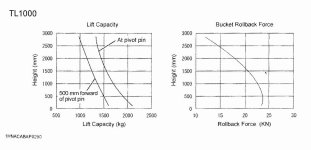

If you have your kubota loader manual for your M9540, they plot it all out on a nice curve.

This is my LA844 loader. The higher you go the less force you have. And if you recall there are many times members on here are lifting a pallet or something that is pushing the limits of their loader, and they can only lift it 3 or 4' then it stops. This lift/height curve explains that