svcguy

Gold Member

- Joined

- May 30, 2005

- Messages

- 362

- Location

- West Kootenays, British Columbia

- Tractor

- Yanmar YM240D / Massey Ferguson 135 / New Holland TN75F / Pasquali 988 and 997 / Goldoni 20A, 226 and Maxter 70RS / Ferrari 76 and 85 / Holder A50 / Valpadana VMC 180 / Long 610 4WD

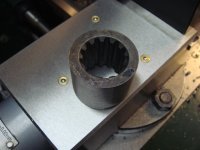

I have a TU205F. TU series have an external driveshaft from the engine to the transfer case / transmission and I have damaged the universals using the lower ranges on the tractor. I have been able to patch them back together, but this last failure is pretty serious. Two questions:

Has anyone successfully upgraded to a heavier universal on the TU series?

Has anyone found an affordable TU universal anywhere?

The universals are a 13 spline metric and pretty specific, but there may be a Japanese car or other tractor that uses a similar setup. Any information would be greatly appreciated.

Thanks,

Tom

Has anyone successfully upgraded to a heavier universal on the TU series?

Has anyone found an affordable TU universal anywhere?

The universals are a 13 spline metric and pretty specific, but there may be a Japanese car or other tractor that uses a similar setup. Any information would be greatly appreciated.

Thanks,

Tom