Tonicci

New member

- Joined

- Nov 24, 2013

- Messages

- 23

- Location

- KVL, Finland

- Tractor

- Gone,ISEKI TF 330 4wd Hydrostatic, in use Valmet h480 1991,in repair antonio carraro supertrac8400 htm 2005

Hi all.

Greetings from Finland.

I am totally Newbie with this forum and with these small tractors. Never drive one.

However, I just bought from auction TF330 4wd Hydrostatic. At auction was informed, that tractor is working nicely, no smoking... BUT not moving. Auxliary Hydraulics are working.

I will get machine at end of this week, but its nice to know what to do with it.

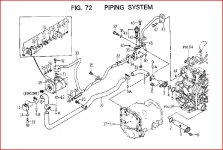

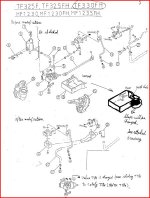

I did find some explosion pictures from Internet, but I need lot of help with this project.

1. Where to start trouble shooting. Could it be simple problem or more serious...?

2. Step by step instructions with photos perhaps,

3. Links for spare part shop in Europe. (I live at Southern Finland)

I have repair all my machines, cars, tractors, motorbikes etc allways. so I understand basics and also basics from pneumatic and hydraulics , but these small tractors are totally new for me.

If this is expensive damage, one option is to throw away whole gearbox and install Hydraulic pump after clutch and then add strong hydraulic drive motor, so machine is possible to drive from one pedal. Would be good for snow works. Suitable Pump I have all ready. I dont need so much speed...

Previously I did have ford 4000 with snowblower, but it was frustrating to use it with manual gears. Too slow and too big to my yard. windows are too close..

So back in bussiness.

How to get this machine moving/ to working condition??

Also instruction manual would be great to find.. I dont know, what all features it have.

My E-mail is skywalker.t@gmail.com

Greetings from Finland.

I am totally Newbie with this forum and with these small tractors. Never drive one.

However, I just bought from auction TF330 4wd Hydrostatic. At auction was informed, that tractor is working nicely, no smoking... BUT not moving. Auxliary Hydraulics are working.

I will get machine at end of this week, but its nice to know what to do with it.

I did find some explosion pictures from Internet, but I need lot of help with this project.

1. Where to start trouble shooting. Could it be simple problem or more serious...?

2. Step by step instructions with photos perhaps,

3. Links for spare part shop in Europe. (I live at Southern Finland)

I have repair all my machines, cars, tractors, motorbikes etc allways. so I understand basics and also basics from pneumatic and hydraulics , but these small tractors are totally new for me.

If this is expensive damage, one option is to throw away whole gearbox and install Hydraulic pump after clutch and then add strong hydraulic drive motor, so machine is possible to drive from one pedal. Would be good for snow works. Suitable Pump I have all ready. I dont need so much speed...

Previously I did have ford 4000 with snowblower, but it was frustrating to use it with manual gears. Too slow and too big to my yard. windows are too close..

So back in bussiness.

How to get this machine moving/ to working condition??

Also instruction manual would be great to find.. I dont know, what all features it have.

My E-mail is skywalker.t@gmail.com

Last edited: