I grew up with a JD 24T baler, so hopefully I can help a bit...

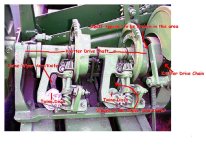

The "shaft that drives the knotters", I would assume, is the main shaft, or "axle" that they are mounted on. It looks as if this shaft may be broken as it looks like the whole knotter assembly is sagging a bit on the RH side where the drive sprocket is.

Just looking at the picture, you might have other problems as well...

- Where is the knife/wiper arm on the RH knotter? It's clearly visible in the left knotter, but the right, it's invisible. The knotter drive wheels appear to be in the same position for both knotters, so the knife/wiper arms should be too... but they're not. It's probably broken, and will need to be replaced.

- Check the twine discs on both knotters. The notches in them should not be worn and should have square edges. If they are excessively worn, you're going to have problems with the knotters not tying. The discs on the RH knotter look pretty worn.

I've attached a picture illustrating what I'm talking about above.

Not from the picture, but things to check anyway...

- Check the bearings/bushings on the connecting rod for the plunger. A couple thousandths of play is OK, but if they're really sloppy, that's more repairs that you're going to have to do.

- Check the plunger knife. Should be sharp and not excessively worn.

- Check the condition/thickness of the metal in the bale chamber, especially in the area of the tension adjustment springs behind the knotters. Lots of bales through the machine means this metal will get worn very thin, and could be worn completely through. More potential repairs.

- Check that both needles are not bent/broken, and are in time with the plunger. Especially check this AFTER the repair to the knotter shaft. Any time that the knotter drive chain is removed, the baler must be re-timed, or else you could (or will) break the needles. The 24T has a safety plunger stop that will stop the plunger if things aren't were they should be at the proper time... I"m not sure if the 14T has this feature as well.

- Check the condition of the U-joints in the PTO shaft... balers are hard on U-joints.

- Check the condition of the bearings in the auger in the pickup.

- Make sure that the hay fingers are in time with the plunger.

- Check for missing/broken pickup teeth.

That's about all I can think of right off hand. Looks like they've got the baler cleaned up pretty well, so any worn/damaged areas should be easier to see. Check extra carefully any areas that have been repainted.

The JD 14T/24T's were both excellent balers, and because of that, most farmers (at least around here) didn't get rid of them until they were absolutely completely worn out. So any time you're looking at a used one, it's wise to give it a thorough checkout so that you're not investing in a money pit. But, if everything looks good, you should be getting a good baler. They just aren't spring chickens anymore

. Since this one has a broken knotter shaft (I've never seen or heard of that happening before), I'd be kind of leery about this one...

If possible (I know it's getting to be the wrong time of year for this, but

) I'd have the dealer bring it over on a "Try before buy" basis. If it missed 1 bale out of 100, I'd pass on it, unless you aren't afraid to open up your wallet for parts. As these balers get older, the knotters are usually what gets them traded in for a new machine... you can keep throwing new parts at them, but everything is just so worn that they won't work properly anymore, even with all new parts. The knotters have to be nearly Perfect to work properly.

Good Luck with your purchase, shop wisely!