SFish

Silver Member

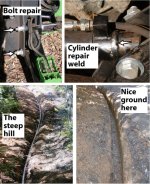

I am using my 3320/447 hoe/9" bucket to dig about 4,000 ft of water line trench from a high point where the well and water tanks are to my new house site, mostly on old logging roads. I am digging on a ridge line with stretches of very heavy clay, decomposed sandstone, and lots of roots that make for tough digging, and I have completed about 1,000 ft. One recent downslope was so steep that I had to loosen the surface with the hoe to back up it (R4 tires), and while digging hydraulic oil began spraying out of the back of one of the stabilizer cylinders.

What I found was that the lower pin on the stabilizer had pulled out, shearing one of the 1/4" cotter pins, and this allowed enough torque to be applied to the pin on the back of the cylinder to break the weld on the plug. I think what happened was that the torque on the stabilizer on the steep hill bound the pin and inched it back shearing its cotter pin.

I have had good luck with my dealer with several warranty repairs (mostly hydraulic lines) but they wouldn't cover this one. So I ordered a new cylinder ($690, ouch!), but when I went in to pick it up they looked at the broken one and sent me to a good welding shop. The weld ($40) is good, but I had to pay ~$120 for JDs restocking fee for returning the new cylinder. I could have fought this, but I got off relatively cheap and wanted to keep a good relationship with the service manager.

I solved the pin problem by replacing all four with 3/4" bolts, double nutted. So I suggest that anyone who is digging in a situation that stresses the stabilizers keep an eye on, or replace the pins, and explore repair options before ordering an expensive part.

Steve

What I found was that the lower pin on the stabilizer had pulled out, shearing one of the 1/4" cotter pins, and this allowed enough torque to be applied to the pin on the back of the cylinder to break the weld on the plug. I think what happened was that the torque on the stabilizer on the steep hill bound the pin and inched it back shearing its cotter pin.

I have had good luck with my dealer with several warranty repairs (mostly hydraulic lines) but they wouldn't cover this one. So I ordered a new cylinder ($690, ouch!), but when I went in to pick it up they looked at the broken one and sent me to a good welding shop. The weld ($40) is good, but I had to pay ~$120 for JDs restocking fee for returning the new cylinder. I could have fought this, but I got off relatively cheap and wanted to keep a good relationship with the service manager.

I solved the pin problem by replacing all four with 3/4" bolts, double nutted. So I suggest that anyone who is digging in a situation that stresses the stabilizers keep an eye on, or replace the pins, and explore repair options before ordering an expensive part.

Steve