jimgerken

Veteran Member

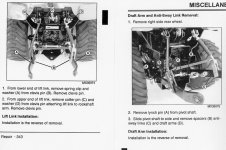

My friend just got his new 2305, and put on a boxblade, and is working it. But he has one objection. The turnbuckles don't go far enough to stabilize the 3 point so his boxblade sways side to side a few inches. I am guessing the turnbuckles or draft arms, or related, are assembled incorrectly. Does anyone have a photo handy, closeup of the three-point area, for reference? He says his turnbuckles are already tightened until the threaded ends touch inside the cast center double nut deal, so no way it can be tightened any more. Must be in the wrong hole, or what? Thanks for photos or anything you can suggest.