farmerwanttobe

Member

- Joined

- Dec 23, 2011

- Messages

- 34

- Location

- Springfield, Missouri

- Tractor

- 2004 Fendt 209 P, 2014 Massey Ferguson 5612, 1998 John Deere 5510N

Hello,

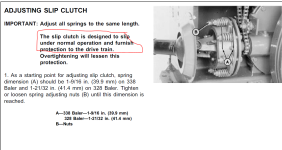

I bought a used John Deere 336 baler. I baled about 200 bales fine. While baling, I noticed the fly wheel had sheered a pin. But it was still baling. I shut it down. the flywheel was spinning free. Started back up and still was making a bale. I thought a flywheel sheer pin would shut you down? I did replace it and maybe it baled a little better. Does anyone have any thoughts on this.

Thanks All

Steve

I bought a used John Deere 336 baler. I baled about 200 bales fine. While baling, I noticed the fly wheel had sheered a pin. But it was still baling. I shut it down. the flywheel was spinning free. Started back up and still was making a bale. I thought a flywheel sheer pin would shut you down? I did replace it and maybe it baled a little better. Does anyone have any thoughts on this.

Thanks All

Steve