Hello!

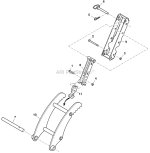

I am embarking on a project to build a thumb for the model 48 backhoe on my JD 4600 tractor. Here's a pic of the model held in place by magnets.

Problem is, the tractor is not near by, so I can't measure this. I need to know what the diameter is of the bucket pivot pin. I want the thumb to use the same pivot point as the bucket, so I'll need to get a longer pin. Need to know what diameter.

One more question: What grade of steel would this pin be?

Thanks!

Dan

I am embarking on a project to build a thumb for the model 48 backhoe on my JD 4600 tractor. Here's a pic of the model held in place by magnets.

Problem is, the tractor is not near by, so I can't measure this. I need to know what the diameter is of the bucket pivot pin. I want the thumb to use the same pivot point as the bucket, so I'll need to get a longer pin. Need to know what diameter.

One more question: What grade of steel would this pin be?

Thanks!

Dan