Bob_Trevithick

Platinum Member

What\'s hard on hydraulic systems?

As I was working with the front blade the other day, I noticed that if I lifted it fully, the engine would imediately begin to sound like it was working harder. So, of course, I would quickly release the SCV.

This led me to wonder.. what sort of things are rough on hydraulic systems? The only one I'm sure of is the one the manual mentions, having the rockshaft "speed of drop" valve locked and then trying to move it. (As an aside, why is it called a "rockshaft"?)

Any others? I'm totally new to hydraulics, and would just as soon learn as many lessons as I can the easy way! /w3tcompact/icons/smile.gif

Thanks,

Bob

Bob Trevithick

As I was working with the front blade the other day, I noticed that if I lifted it fully, the engine would imediately begin to sound like it was working harder. So, of course, I would quickly release the SCV.

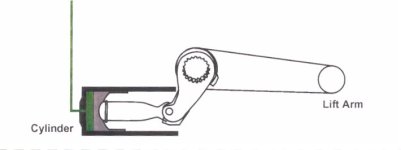

This led me to wonder.. what sort of things are rough on hydraulic systems? The only one I'm sure of is the one the manual mentions, having the rockshaft "speed of drop" valve locked and then trying to move it. (As an aside, why is it called a "rockshaft"?)

Any others? I'm totally new to hydraulics, and would just as soon learn as many lessons as I can the easy way! /w3tcompact/icons/smile.gif

Thanks,

Bob

Bob Trevithick