sodamo

Super Star Member

- Joined

- May 20, 2004

- Messages

- 16,982

- Location

- Big Island, HI

- Tractor

- LS XR4140H (Mine) BX2380 (wife’s)

After not using my backhoe for the past year, this week I was ready to start a major trenching project. Finally, got the hoe mounted and about the 3rd attempt to scoop some dirt all H broke loose - hydraulic fluid.

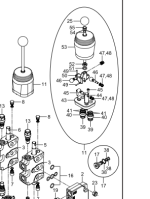

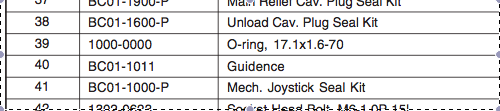

Appears that some sort of plastic/nylon piece broke in the Boom portion of the control valve. You can see it at end of red arrow.

Judging from the exploded parts manual, I'm guessing it is item #40 - Guidence. So I have ordered replacement and new O rings.

If any words of wisdom out there, I'd be appreciative. I haven't disassembled anything yet, most likely Sunday.

Thanks

Appears that some sort of plastic/nylon piece broke in the Boom portion of the control valve. You can see it at end of red arrow.

Judging from the exploded parts manual, I'm guessing it is item #40 - Guidence. So I have ordered replacement and new O rings.

If any words of wisdom out there, I'd be appreciative. I haven't disassembled anything yet, most likely Sunday.

Thanks