4shorts

Elite Member

Ken personally I feel that a 4" pipe will look out of place. I pondered using a 4" and thought it would give the look of not belonging to the machine. Anything over 3" is out of limits for me but it was my goal to add this to my machine to make it look as if it came with the tractor.

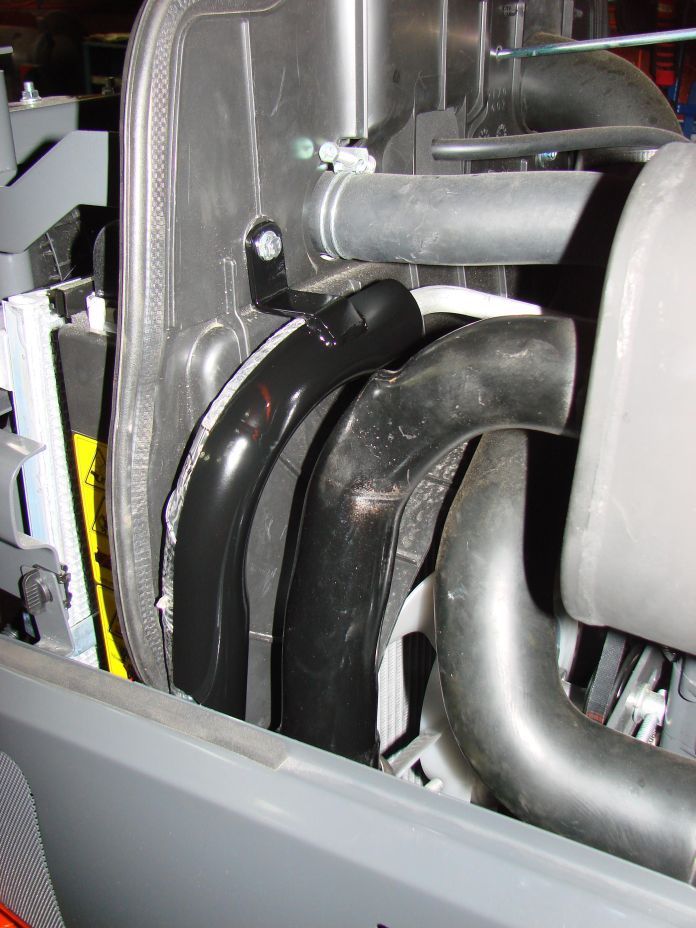

I also wanted to point out a few more things about the stack adapter box. This design is very strong yet practice. By designing ad building it this way I accomplished a number of things.

- The box has the same bolt pattern as the lower bolts in the FEL so no other holes had to be drilled.

- The extension that you see on the box not only gives the 48" exhaust stack extra height but it also gives it added stability because it acts as a double pipe and the stack is swelled just enough to slide down over the pipe and a simple clamp keeps it in place and hardly noticeable. If you use a longer stack without an extension I think you'll have a lot of shaking in the longer stack when operating the machine.

- The bends that you see in the rear of the adapter box was put there for added strength.

Don't forget to use a flex section in the system to absorb any vibration andvalsomaboiding cracking in other parts of the exhaust system. I also used stainless steel V clamps to attach the system. I did this for easy removal if the system needed to be removed.

These items I mentioned because they are the items I considered while I was designing my exhaust.

I also wanted to point out a few more things about the stack adapter box. This design is very strong yet practice. By designing ad building it this way I accomplished a number of things.

- The box has the same bolt pattern as the lower bolts in the FEL so no other holes had to be drilled.

- The extension that you see on the box not only gives the 48" exhaust stack extra height but it also gives it added stability because it acts as a double pipe and the stack is swelled just enough to slide down over the pipe and a simple clamp keeps it in place and hardly noticeable. If you use a longer stack without an extension I think you'll have a lot of shaking in the longer stack when operating the machine.

- The bends that you see in the rear of the adapter box was put there for added strength.

Don't forget to use a flex section in the system to absorb any vibration andvalsomaboiding cracking in other parts of the exhaust system. I also used stainless steel V clamps to attach the system. I did this for easy removal if the system needed to be removed.

These items I mentioned because they are the items I considered while I was designing my exhaust.