My Hoe

Platinum Member

- Joined

- Oct 31, 2010

- Messages

- 560

- Location

- NYS--Various Parts

- Tractor

- Kubota B3000HSDCC, BH77, 5' Belly Mower, 6' Hyd. Angle Plow

Hi all,

Now, I'm trusting you boys and girls not to go buying this machine out from under me--LOL but not really kidding.

Of course, if I pass on it, I'll be sure to let you all know. I have a friendship, of sorts, with the dealer's owner, so I think he'd take kindly to anyone I recommended to him, as a buyer, if I pass.

What this "War and Peace"-length diatribe is all about, in short, is--will the barn we bought hold up a TLB L5740? Or even just a B3030HDCC TLB, IF I could find one? If this subject is not of interest to you, please don't torture yourself reading it--your time is YOUR time--please don't spend it where it doesn't bring you enjoyment, only to help me.

Or, if the Mod Squad thinks this post belongs elsewhere, please move it (hopefully not into the trash? LOL)

To make sense of this, I gently suggest you see my post immediately AFTER this one, as that shows the ONLY interior pic of the barn, and it's weird "parapet/4 quadrant" layout, that I go on about, ad nausem. I had added it here, but it got "bumped" when I added more photos. Who know? LOL

See, I originally uploaded pics of the outside of the barn, but I guess you're only allowed five pics per post, which I guess is generous, compared to a lot of sites.

Also, I apologize for any repetition here--I'm semi-serious "in crisis" in about 3 or 4 different ways (please knock on wood three times for me? Thanks--I got the OCD. Anyway, I thought writing this would be a good stress-reliever--but now that I'm in my fourth hour of it, however, I'm not so sure.... LOL

Here is the machine:

KUBOTA L5740HSTC 40 HP to 99 HP For Sale At TractorHouse.com

Now, the following "Great Plains Kubota" site (below) USED to have EVEN MORE SPECS than Kubota's official site--like THE WEIGHTS OF THE VARIOUS MODELS, for example. :confused2:

Yet I can't find it anymore--you used to be able to pull up a pic, with an EXTENSIVE SPEC LIST, on, say, a B3030HDCC and an L5730. You could then compare their specs SIDE-BY-SIDE, by looking at them, and see a pic of each machine at the same time, as well. :thumbsup:

NOW, however, all I can find on this site (below) is a watered-down version, comparing backhoes themselves. Observe:

Kubota vs Woods 2010 vs 2008 B26 Model - Backhoe vs BH80-X (8 ft.)

I'm thinkin' Kubota put the "kibosh" (sp?) on Great Plains, for giving EVEN MORE INFO than I could find on Kubota's own site? I dunno....

The reason I care is, IIRC, the weight of a B3030HDCC, was roughly 2,200 lbs., without FEL and Hoe, I believe. Is that correct?

I also think, IIRC, that the L5740 weighed (without FEL and Hoe) over 4,000lbs. Is that correct?

My Problem, Again--Is the SECOND FLOOR (i.e., wooden planking) of the Barn Strong Enough for an "L"? Or Even a B3030HDCC?

We have just purchased a house with an old "post and beam construction" barn, which the owner beautifully re-skinned, 10 years ago (he is a contractor) with laser-straight steel siding and roofing.

My question has to do with the ability of this barn to handle the weight of an L5740, with FEL and 8' Woods hoe, plus 200-600lbs. "on the hook" (hoe). We understand that there are "barn experts" that may come, for a fee, or just for their own edification/enthusiasm, to render opinions, educate the owners, and generally help preserve these vanishing, beautiful buildings.

However, I haven't found this expert yet, and I'm afraid the tractor I'm interested in might "slip away" if I don't make an offer on it, prior to getting my "barn expert's" expertise.

So that leaves you guys and gals! IF you're interested in reading a novella and then offering commentary, of course. LOL

The barn is 38' by 40' by however high (50'?). However, that interior space, on the second (upper, wooden-planked floor) is LARGELY EATEN UP by these weird, approx. 10' x 10' "quadrants," that are formed by 8" hand-adzed beams. These "quadrants" take up the outer, four corners of the barn.

These "quadrants," (please go see my next post, which has a poor pic of the end of one, looking from the center of the barn, near the overhead door, on the second floor) with their low, 3'-4' high "parapets," are really just made up of the 8", hand-adzed horizontal beams, and the material you see UNDER that beam are just simple barn boards, not holding any weight. The WEIGHT, if I understand what I'm seeing, is that, downstairs, somewhere under that horizontal, 8" beam, are 10" vertical beams, sitting on the original concrete of the barn. (I'm sorry the pics aren't better--I can possibly find some more later.) You may be able to see the brighter, yellowish END of one of these 8" horizontal beams, where the P.O. chainsawed them off.

Originally, these 3'-4' high, 8" beams ALSO ran ACROSS the floor of the bar, so that you couldn't have driven anything from the front of the barn to the back (I don't get it?). The P.O. cut them with a chain saw, and he said they "were so hard they were almost petrified--you should have seen the sparks flying when I sawed them." And since he's a successful, 60-70 y.o. contractor, and this is a "post-and-beam construction" barn, I'm SURE he'd have known it if he was hitting nails with his saw. IOW, this wood is TOUGH.

But does that make it strong? I dunno.... The barn is straight as an arrow--he said he had to do ZERO "furring strips" before he ran is 7/8" x 4" horizontal "stringers, that he then bolted to, from the outside, with gasketed hex-head bolts, to hold the skin on, 10+ years ago.

After he removed those lower, 8" beam "ties" that connected each quadrant to it's cousin, across the barn, and then he compensated for this by installing 2" x 8"'s (or 2" x 10"'s?), overhead, in a "collar tie" arrangement, so he feels he adequately made up for the removal of the lower beams, so that, again, one COULD drive straight in, to the back side, IF one trusts the barn planks to hold.

The pic showing the modern, metal, overhead door makes it look like that door is 14' high, but it's not--it's only a 10' high door. IOW, the barn looks GIANT in these pics, but it's still only 38' x 40', but it's cute as a button, and has a lot of charm, downstairs, with a "milk room," and all the various treasures and delights that those who appreciate barns, (as I do, but I know BEANS about their construction and strength), do.

As I will mention later, he parked a 60's AMC "Scrambler" (3,000lb--I looked it up) just inside the overhead door he installed on one side, which I described above, which also gives you the only interior view ofthe barn, with one ofthe cut-off "parapets" showing.

But he did not feel comfortable driving it any deeper into the barn. He even reinforced the floor, JUST under the car, as I will explain, as he obviously felt he was "pushing it."

If you look to the extreme left hand side of the photo marked "10 Inch Beam, Downstairs," you can just make out the dark, end of one of two 4" x 6" beams the P.O. felt necessary to hold up his 3,000lb. muscle car. But LOOK how the thing is built, generally!

For those of you NOT familiar with the "Post and Beam Construction" method, it uses "mortise and tenon"-type wooden joints, literally PINNED together, as you can see, IIRC, by FOUR, vampire-killing-spike-shaped wooden pegs at that joint (for any of you "Dark Shadows" fans out there--I know, showing my age). Generally, I've noticed there's only TWO such spikes at most junctures, so that one must have been something special. The

Also, if you look at the photo marked "General, 3' On Center, First Floor, 8 inch Floor Joists." you will see what I mean about me not worrying about falling through the whole floor with the tractor--those floor/ceiling joists (what are they called when you're downstairs, CEILING joists, I guess?) are, to my eye in the photos, and my memory, about 3' on center, and, like the rest, 8" hand-adzed. (Only the vertical members seem to be 10" and NOT ALL of them ARE 10"--some are only 8", IIRC, but I think MOST of the vertical members, downstairs, ARE 10".)

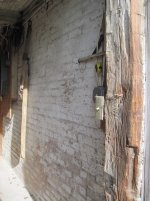

If you will see the photo named "Downstairs, Livestock Area--Brick Wall," you will see that there are a fair number of BRICK WALLS in the downstairs area. I'm an English Major, with a grad. degree, who likes to work on cars--I CANNOT TELL if these are "load bearing walls" or not, and I guess if they're not under where the P.O. used to park his Scrambler, OR, more importantly, WHERE I HOPE TO DRIVE THE TLB, then I guess it doesn't matter, but it still feels like there's a lot of strength here.

I have a business model in mind that would involve me placing not-so-heavy items inside these quadrants, for storage, by lifting them OVER the parapets, with the hoe--probably with those neat "T-hooks" (or "J hooks?) that I saw on here on TBN that had cut holes in their hoe bucket for.

The barn originally appears to have had a third floor, as most barns do, for a "hay mow." I don't know if or why the P.O. removed this, but it's gone--all but for the beams which held (part of?) it up, and an old ladder, made out of TREES, runs up the side, to the peak of the roof.

I don't know why it was done that way, but these hand-adzed "8" quadrant" beams (which enclose each 10' x 10' "quadrant" do NOT look like any more can be removed--apparently, they went ALL THE WAY ACROSS THE BARN FLOOR, at like 3-4' high, but the P.O. DID cut them so that there is an open area to WALK around in, to reach the quadrants.

The bottom floor of the barn is poured concrete, which the P.O. re-did in a section (for smoothness?) for a workshop, but the rest is the ol' rough, strong stuff-which is fine.

The upper barn floor has the traditional, uneven-width, up to 16" wide x 2+" thick planks, but the P.O. only parked a 3,000lb muscle car JUST inside the overhead door he installed, and he reinforced the upper, planked-wooden floor, by "sistering" in, UNDER the second floor, two 4" x 6" wooden beams, under where his AMC "Scrambler" sat, and he was apparently afraid to drive it in more than he needed to to shut the garage door, best visualized by looking at the tall, overhead door (in my follow-up post, unless all 8 photos will fit in this one, and I just don't see them?). He drove in just far enough to shut the door, and that's as far as he dared go.

Since he is older and wiser than me, not to mention a contractor, I come, hat-in-hand, to the collective "BRAIN TRUST" here.

So...My Questions Are:

1. WHO KNOWS ABOUT THESE OLD POST-AND-BEAM BARNS, and HOW MUCH WEIGHT THEY CAN HANDLE? I really don't even want to put this beautiful piece of historical architecture at risk, beyond possibly having to replace a floor plank, should a break one, and "call it a day."

That would, of course, mean I bought too heavy of a tractor.

There are no Kubota dealers for miles, but I thought if I could get any green or red TLB's OF AS CLOSE A WEIGHT AS POSSIBLE to the TLB I plan to make out of the L5740 in question, then I could test the barn that way. I could simply say "I want to see how comfortable I am moving around in this confined space, and hopefully, a dealer would drop one off for an hour or so. I have read about dealers doing this, for a new tractor purchase, here on TBN.

Is this an UNCOMMON courtesy, awarded only to "10 Tractor and Up" buyers like our beloved John Thomas, or in this economy, is this something I can actually expect a non-Kubota dealer to do?

My father, who was in heavy construction all his life (cranes, dozers, 977's, you name it) says that my plan to S-L-O-W-L-Y roll around, with the FEL and hoe buck only 1-2" above the 2nd floor floor planks, is a good way to test the barn. IOW, if I break a plank, the buckets (front and rear) should keep me from doing more than merely ruining a single plank, and the the 8", 3' on center floor beams/ceiling joists (if you're downstairs) should allow the buckets to distribute the weight until I can gingerly get the **** out of there. (I'll wear a motorcycle helmet too, I guess, to protect my noggin, in case this DO get more exciting than we anticipate.

But there's no space big enough, downstairs, between those 8" beams, to allow more than a front (or rear) wheel to drop down, and again, shouldn't the buckets dragging on the planks prevent more than a cracked floor plank?

I did some simple math, and came up with a hay wagon weight of 4,000 lbs., but I recall seeing, in Simplicity's 1960's, beautiful, color catalogs (available free on line, but I can't take the time now) an ad that said:

"A 7 hp. GARDEN TRACTOR pulling 7,000 lbs. of hay." (paraphrased, but I'm pretty confident on the numbers.

So...could those old barns take 3.5 TONS/7,000lbs of hay weight? PLUS horses, people, etc....?

I arrived at my own, 4,000lb. figure, thusly:

An 8' x 12' wagon, with each layer containing two rows of 6 bales each (I haven't thrown hay since I was a kid, but aren't bales like 2' x 4', and weigh 60-80lbs each? I figured 60lbs., to be conservative.

So, 12 bales per layer, times 60 lbs = 720lb. per layer.

I figured 4 layers high would be about it, in the horse drawn days, but maybe that's too high to be real?

IF it's not, that's 4 layers (at 720lb per layer) times 2,880lbs.

Plus wagon--WAG? 1,000 lbs?

Plus two horses, at 1,100lb. each (Wikipedia's "average" horse wt.) = 2,200 in horses. (And the reason I mention this is I believe many of these barns were designed to be driven THROUGH, (thus adding the horses weight, too) but I could be wrong about that.

Clarification, anyone?

So:

Hay = 2,880lbs.

Horses = 2,200lbs.

Wagon = 1,000lbs. (is that too high?)

_________________

6,080 lbs. Am I higher than a box kite right now? LOL

Next question: MAYBE THEY NEVER PUT THE HORSES IN WHILE THE HAY WAS IN, AND JUST BACKED THE TRAILER IN? If so, now I'm down to 3,880lbs.

And I believe the L5740 weighs 4,000lb. WITHOUT FEL AND Hoe, right?

What is the weight of an L's FEL? I know the Woods hoe is supposed to be roughly 1,000lb. If the FEL is 800lb. (WAG) then the TLB would weigh 5,800lbs., PLUS up to say, and additional 600lb. in the item being moved.

So, I'm then at 6,400lbs. Nervous yet? I am! LOL

And can a barn that's now dry as a bone, straight as an arrow, etc..., be counted on to have it's original strength?

I honestsly haven't a clue..., so PLEASE CHIME IN ON ANY AND ALL OF THIS STUFF.

The upper floor/lower ceilings joists are 8" hand-adzed beams, on like 3' centers, I believe, and the uprights are UP to 10", hand-adzed.

*Phew!* "Question #1" (and it's dozen, unlabeled sub-parts, is now over--for anyone still reading.:laughing:

2. What is the weight of this L5740 tractor, since I can't find it on Kubota's site. I will be adding a big, Kubota FEL, and a Woods BH80X, which I understand with subframe will be about 1,000 lbs. The stuff I'll be moving will be relatively light, say 200-600lbs. (Parts, antiques, a snowmobile, etc...).

I should explain (if I've done so already, please forgive me--sober, but up two days....) that I don't mind driving around on the second floor, with "watchers" in safe corners, on the (concrete) first floor, with walkie talkies, and I planned to keep the FEL 2" off of the floor, and the hoe's bucket 2" off the floor. That way, I figure I may drop a (front?) wheel through a 16" barn floor plank, which will break my heart, but there IS a lumber yard right down the road, so I would have them roughly simulate the broken plank, round the edges to match it's mates, and then I would weather it outside for a while, then install it (or higher it done, given my injuries).

Or possibly just REPAIR the old plank, with major "sistering" of planks underneath, IF I could gain access to the broken portion. The first floor of the barn is fairly tight, with at least 6 different "rooms," so you can't count on access from the bottom side, necessarily.

But I'd rather not break the floor, and buy TOO HEAVY OF A TRACTOR to begin with.

Sidebar: I Can Hear Your Questions Already--What ELSE WILL You Use the L For?

a) probably snowblowing.

b) possibly mowing, if I can afford the mower--are L's the ones with the "drive over decks"? Because I ain't horsing one in from the side, I can tell you that much.

The property is either under 2 acres or possibly we'll get another 2 acres (please knock on REAL wood for me, THREE TIMES, re: this, as I'm a little OCD--and as you can tell, the treatment ain't working.). IF we got the extra land, it includes a wet gulch, which I'd like to find some metal "bridge decking," scrapped, and drag around and make a little, 30' bridge. I can't just build a road, so I'd have to put in a culvert, and I don't know what the DEC/NYS/EPA would have to say about that, much less the Town. If figure, if I got a hold of some bridge decking, and the town didn't like it, I could scrap it or use it elsewhere.

IF we got the extra land, it includes a wet gulch, which I'd like to find some metal "bridge decking," scrapped, and drag around and make a little, 30' bridge. I can't just build a road, so I'd have to put in a culvert, and I don't know what the DEC/NYS/EPA would have to say about that, much less the Town. If figure, if I got a hold of some bridge decking, and the town didn't like it, I could scrap it or use it elsewhere.

3. How Much Did The Hay Wagons of Back-in-the-Day (post and beam construction, I'm told, dates it to 150-200 years old!) WEIGH?

4. Because this is not a "Grand L5740," does that mean:

a) no tilt wheel?

b) no "quick pin" TPH (or whatever Kubota calls it?)

c) no "Position Control?"

5. It DOES APPEAR have the SUSPENSION SEAT, which I may need, due to recent back surgery (please knock on REAL wood for me, A-GAIN) as I'm nervous about "jinxing" my chances at making a good recovery. THANK YOU VERY MUCH--no, there's no "mental" test required to join TBN, at least none I was aware of--LOL :laughing:

a) Has anyone had any experience with this "suspension seat?"?

b) Is there any "dampening" action to the suspension seat, or is it just "boing-boing" and how effective is it? It SEEMS like a much better deal than just having a hard-mounted seat. I'll have turfs, btw, which should soften the ride further, so I've read.

6. CAN the suspension seat be RETROFITTED into the B3030HDCC, or was it actually offered as an option?

7. How much should I be willing to pay for this tractor, sans back hoe, which I understand will add $7,500-9,000., if I get the Woods?

8. What other differences are there between an L5740 and a GRAND L5740?

Confession: I don't NEED 60 hp. I probably need like 26-30 hp. (might get a snow blower). But this one looked nice, and I like the extra weight for dirt work, etc.... Just not at the expense of breaking my barn--even a floor plank will be extremely painful to me.

9. Can anyone direct me to the portion of Great Plains Kubota's site that USED to allow the side-by-side comparison of specs that I've described? It was SO HELPFUL! In fact, I learned of it from a fellow TBN'er, and was using it only a few months ago!

10. Are L5740's THREE CYLINDERS or FOUR? I remember seeing SOME L's that were three cylinders. The reason I ask is, I HATE vibration, and do NOT want anything to do with the "only affects some units" vibration problems that I've read about with SOME, but not ALL, four cylinder B3000's, B3200's and even, I believe, some B3030's.

11. More importantly, do these L5740's have ANY history of ANNOYING ENGINE VIBRATION PROBLEMS? I've not been in the "L" market before (and probably shouldn't be now, right? LOL) and I've not seen any comments on "L's" having the "vibration issue" of the smaller, four cylinder machines I mentioned.

12. Does the 407 hours bother anyone?

Any "known pattern failures" on these machines I should look for, beyond the normal leaks, wear, bent FEL arms, etc...? Noises?

13. I know tractors don't have "model years," but perhaps an experienced "L" owner could ballpark this machine's age?

14. Of course, now I'll be "married" to the Kubota QA system, when I had planned to buy a B3030HDCC, and have that popular SSQA system (ADI's kit, I believe?) fabbed on by a local fab shop, as my welding is waaaay below that level of quality. But I only forsee the need for GOOD forks and the bucket. Am I overlooking something?

15. What Else Am I Possibly Overlooking, Generally?

Hit me--I can take it--I'm not big physically, but I've got a strong heart, so lemme have it, please.

16. Bent FEL Arms? In the top row's FAR RIGHT thumbnail, it looks like the left front corner of the bucket is "flying." I believe this used Kubota dealers has a new shop (with hopefully a flat floor) so I could check tire pressures, and try to determine if something is bent.

a) Any better way to do this? I was thinking of buying some 12' 1" x 4"''s, and a looong level, just to check his floor, but let's say it is tweaked. I've got OCD, so that WILL bother me, but:

b) Is it more of a negotiating point, or would you guys run, if the FEL is twisted? IF it's twisted, how much off his "final price" would you lean on him for--$500.? $1,000? More?

17. The problem, again, is the barn planks. I've been told I could cover them all with 1" plywood or even particle board, and VASTLY increase their load-bearing ability. Opinions? My "bugaboo" about that is, I WANT to see those barn planks. And I don't want to buy, then screw together, 20-30 sheets of anything that's 1" thick.

And Now, a Favor: For those so inclined, I would appreciate, for clarity's sake, that if you take on one of my questions, you'd be so kind as to refer to it by it's number(i.e., 1-17 or whatever I'm up to), as I know this is a long, rambling "My Hoe" post, and I'm sure OTHERS would appreciate the quick reference to my question numbers just as much as I would.

If this doesn't get me kicked out of the TBN'ers' club, then you guys are EVEN KINDER and MORE GENEROUS than I already knew you to be.

Thanks again,

My Hoe

Now, I'm trusting you boys and girls not to go buying this machine out from under me--LOL but not really kidding.

Of course, if I pass on it, I'll be sure to let you all know. I have a friendship, of sorts, with the dealer's owner, so I think he'd take kindly to anyone I recommended to him, as a buyer, if I pass.

What this "War and Peace"-length diatribe is all about, in short, is--will the barn we bought hold up a TLB L5740? Or even just a B3030HDCC TLB, IF I could find one? If this subject is not of interest to you, please don't torture yourself reading it--your time is YOUR time--please don't spend it where it doesn't bring you enjoyment, only to help me.

Or, if the Mod Squad thinks this post belongs elsewhere, please move it (hopefully not into the trash? LOL)

To make sense of this, I gently suggest you see my post immediately AFTER this one, as that shows the ONLY interior pic of the barn, and it's weird "parapet/4 quadrant" layout, that I go on about, ad nausem. I had added it here, but it got "bumped" when I added more photos. Who know? LOL

See, I originally uploaded pics of the outside of the barn, but I guess you're only allowed five pics per post, which I guess is generous, compared to a lot of sites.

Also, I apologize for any repetition here--I'm semi-serious "in crisis" in about 3 or 4 different ways (please knock on wood three times for me? Thanks--I got the OCD. Anyway, I thought writing this would be a good stress-reliever--but now that I'm in my fourth hour of it, however, I'm not so sure.... LOL

Here is the machine:

KUBOTA L5740HSTC 40 HP to 99 HP For Sale At TractorHouse.com

Now, the following "Great Plains Kubota" site (below) USED to have EVEN MORE SPECS than Kubota's official site--like THE WEIGHTS OF THE VARIOUS MODELS, for example. :confused2:

Yet I can't find it anymore--you used to be able to pull up a pic, with an EXTENSIVE SPEC LIST, on, say, a B3030HDCC and an L5730. You could then compare their specs SIDE-BY-SIDE, by looking at them, and see a pic of each machine at the same time, as well. :thumbsup:

NOW, however, all I can find on this site (below) is a watered-down version, comparing backhoes themselves. Observe:

Kubota vs Woods 2010 vs 2008 B26 Model - Backhoe vs BH80-X (8 ft.)

I'm thinkin' Kubota put the "kibosh" (sp?) on Great Plains, for giving EVEN MORE INFO than I could find on Kubota's own site? I dunno....

The reason I care is, IIRC, the weight of a B3030HDCC, was roughly 2,200 lbs., without FEL and Hoe, I believe. Is that correct?

I also think, IIRC, that the L5740 weighed (without FEL and Hoe) over 4,000lbs. Is that correct?

My Problem, Again--Is the SECOND FLOOR (i.e., wooden planking) of the Barn Strong Enough for an "L"? Or Even a B3030HDCC?

We have just purchased a house with an old "post and beam construction" barn, which the owner beautifully re-skinned, 10 years ago (he is a contractor) with laser-straight steel siding and roofing.

My question has to do with the ability of this barn to handle the weight of an L5740, with FEL and 8' Woods hoe, plus 200-600lbs. "on the hook" (hoe). We understand that there are "barn experts" that may come, for a fee, or just for their own edification/enthusiasm, to render opinions, educate the owners, and generally help preserve these vanishing, beautiful buildings.

However, I haven't found this expert yet, and I'm afraid the tractor I'm interested in might "slip away" if I don't make an offer on it, prior to getting my "barn expert's" expertise.

So that leaves you guys and gals! IF you're interested in reading a novella and then offering commentary, of course. LOL

The barn is 38' by 40' by however high (50'?). However, that interior space, on the second (upper, wooden-planked floor) is LARGELY EATEN UP by these weird, approx. 10' x 10' "quadrants," that are formed by 8" hand-adzed beams. These "quadrants" take up the outer, four corners of the barn.

These "quadrants," (please go see my next post, which has a poor pic of the end of one, looking from the center of the barn, near the overhead door, on the second floor) with their low, 3'-4' high "parapets," are really just made up of the 8", hand-adzed horizontal beams, and the material you see UNDER that beam are just simple barn boards, not holding any weight. The WEIGHT, if I understand what I'm seeing, is that, downstairs, somewhere under that horizontal, 8" beam, are 10" vertical beams, sitting on the original concrete of the barn. (I'm sorry the pics aren't better--I can possibly find some more later.) You may be able to see the brighter, yellowish END of one of these 8" horizontal beams, where the P.O. chainsawed them off.

Originally, these 3'-4' high, 8" beams ALSO ran ACROSS the floor of the bar, so that you couldn't have driven anything from the front of the barn to the back (I don't get it?). The P.O. cut them with a chain saw, and he said they "were so hard they were almost petrified--you should have seen the sparks flying when I sawed them." And since he's a successful, 60-70 y.o. contractor, and this is a "post-and-beam construction" barn, I'm SURE he'd have known it if he was hitting nails with his saw. IOW, this wood is TOUGH.

But does that make it strong? I dunno.... The barn is straight as an arrow--he said he had to do ZERO "furring strips" before he ran is 7/8" x 4" horizontal "stringers, that he then bolted to, from the outside, with gasketed hex-head bolts, to hold the skin on, 10+ years ago.

After he removed those lower, 8" beam "ties" that connected each quadrant to it's cousin, across the barn, and then he compensated for this by installing 2" x 8"'s (or 2" x 10"'s?), overhead, in a "collar tie" arrangement, so he feels he adequately made up for the removal of the lower beams, so that, again, one COULD drive straight in, to the back side, IF one trusts the barn planks to hold.

The pic showing the modern, metal, overhead door makes it look like that door is 14' high, but it's not--it's only a 10' high door. IOW, the barn looks GIANT in these pics, but it's still only 38' x 40', but it's cute as a button, and has a lot of charm, downstairs, with a "milk room," and all the various treasures and delights that those who appreciate barns, (as I do, but I know BEANS about their construction and strength), do.

As I will mention later, he parked a 60's AMC "Scrambler" (3,000lb--I looked it up) just inside the overhead door he installed on one side, which I described above, which also gives you the only interior view ofthe barn, with one ofthe cut-off "parapets" showing.

But he did not feel comfortable driving it any deeper into the barn. He even reinforced the floor, JUST under the car, as I will explain, as he obviously felt he was "pushing it."

If you look to the extreme left hand side of the photo marked "10 Inch Beam, Downstairs," you can just make out the dark, end of one of two 4" x 6" beams the P.O. felt necessary to hold up his 3,000lb. muscle car. But LOOK how the thing is built, generally!

For those of you NOT familiar with the "Post and Beam Construction" method, it uses "mortise and tenon"-type wooden joints, literally PINNED together, as you can see, IIRC, by FOUR, vampire-killing-spike-shaped wooden pegs at that joint (for any of you "Dark Shadows" fans out there--I know, showing my age). Generally, I've noticed there's only TWO such spikes at most junctures, so that one must have been something special. The

Also, if you look at the photo marked "General, 3' On Center, First Floor, 8 inch Floor Joists." you will see what I mean about me not worrying about falling through the whole floor with the tractor--those floor/ceiling joists (what are they called when you're downstairs, CEILING joists, I guess?) are, to my eye in the photos, and my memory, about 3' on center, and, like the rest, 8" hand-adzed. (Only the vertical members seem to be 10" and NOT ALL of them ARE 10"--some are only 8", IIRC, but I think MOST of the vertical members, downstairs, ARE 10".)

If you will see the photo named "Downstairs, Livestock Area--Brick Wall," you will see that there are a fair number of BRICK WALLS in the downstairs area. I'm an English Major, with a grad. degree, who likes to work on cars--I CANNOT TELL if these are "load bearing walls" or not, and I guess if they're not under where the P.O. used to park his Scrambler, OR, more importantly, WHERE I HOPE TO DRIVE THE TLB, then I guess it doesn't matter, but it still feels like there's a lot of strength here.

I have a business model in mind that would involve me placing not-so-heavy items inside these quadrants, for storage, by lifting them OVER the parapets, with the hoe--probably with those neat "T-hooks" (or "J hooks?) that I saw on here on TBN that had cut holes in their hoe bucket for.

The barn originally appears to have had a third floor, as most barns do, for a "hay mow." I don't know if or why the P.O. removed this, but it's gone--all but for the beams which held (part of?) it up, and an old ladder, made out of TREES, runs up the side, to the peak of the roof.

I don't know why it was done that way, but these hand-adzed "8" quadrant" beams (which enclose each 10' x 10' "quadrant" do NOT look like any more can be removed--apparently, they went ALL THE WAY ACROSS THE BARN FLOOR, at like 3-4' high, but the P.O. DID cut them so that there is an open area to WALK around in, to reach the quadrants.

The bottom floor of the barn is poured concrete, which the P.O. re-did in a section (for smoothness?) for a workshop, but the rest is the ol' rough, strong stuff-which is fine.

The upper barn floor has the traditional, uneven-width, up to 16" wide x 2+" thick planks, but the P.O. only parked a 3,000lb muscle car JUST inside the overhead door he installed, and he reinforced the upper, planked-wooden floor, by "sistering" in, UNDER the second floor, two 4" x 6" wooden beams, under where his AMC "Scrambler" sat, and he was apparently afraid to drive it in more than he needed to to shut the garage door, best visualized by looking at the tall, overhead door (in my follow-up post, unless all 8 photos will fit in this one, and I just don't see them?). He drove in just far enough to shut the door, and that's as far as he dared go.

Since he is older and wiser than me, not to mention a contractor, I come, hat-in-hand, to the collective "BRAIN TRUST" here.

So...My Questions Are:

1. WHO KNOWS ABOUT THESE OLD POST-AND-BEAM BARNS, and HOW MUCH WEIGHT THEY CAN HANDLE? I really don't even want to put this beautiful piece of historical architecture at risk, beyond possibly having to replace a floor plank, should a break one, and "call it a day."

That would, of course, mean I bought too heavy of a tractor.

There are no Kubota dealers for miles, but I thought if I could get any green or red TLB's OF AS CLOSE A WEIGHT AS POSSIBLE to the TLB I plan to make out of the L5740 in question, then I could test the barn that way. I could simply say "I want to see how comfortable I am moving around in this confined space, and hopefully, a dealer would drop one off for an hour or so. I have read about dealers doing this, for a new tractor purchase, here on TBN.

Is this an UNCOMMON courtesy, awarded only to "10 Tractor and Up" buyers like our beloved John Thomas, or in this economy, is this something I can actually expect a non-Kubota dealer to do?

My father, who was in heavy construction all his life (cranes, dozers, 977's, you name it) says that my plan to S-L-O-W-L-Y roll around, with the FEL and hoe buck only 1-2" above the 2nd floor floor planks, is a good way to test the barn. IOW, if I break a plank, the buckets (front and rear) should keep me from doing more than merely ruining a single plank, and the the 8", 3' on center floor beams/ceiling joists (if you're downstairs) should allow the buckets to distribute the weight until I can gingerly get the **** out of there. (I'll wear a motorcycle helmet too, I guess, to protect my noggin, in case this DO get more exciting than we anticipate.

But there's no space big enough, downstairs, between those 8" beams, to allow more than a front (or rear) wheel to drop down, and again, shouldn't the buckets dragging on the planks prevent more than a cracked floor plank?

I did some simple math, and came up with a hay wagon weight of 4,000 lbs., but I recall seeing, in Simplicity's 1960's, beautiful, color catalogs (available free on line, but I can't take the time now) an ad that said:

"A 7 hp. GARDEN TRACTOR pulling 7,000 lbs. of hay." (paraphrased, but I'm pretty confident on the numbers.

So...could those old barns take 3.5 TONS/7,000lbs of hay weight? PLUS horses, people, etc....?

I arrived at my own, 4,000lb. figure, thusly:

An 8' x 12' wagon, with each layer containing two rows of 6 bales each (I haven't thrown hay since I was a kid, but aren't bales like 2' x 4', and weigh 60-80lbs each? I figured 60lbs., to be conservative.

So, 12 bales per layer, times 60 lbs = 720lb. per layer.

I figured 4 layers high would be about it, in the horse drawn days, but maybe that's too high to be real?

IF it's not, that's 4 layers (at 720lb per layer) times 2,880lbs.

Plus wagon--WAG? 1,000 lbs?

Plus two horses, at 1,100lb. each (Wikipedia's "average" horse wt.) = 2,200 in horses. (And the reason I mention this is I believe many of these barns were designed to be driven THROUGH, (thus adding the horses weight, too) but I could be wrong about that.

Clarification, anyone?

So:

Hay = 2,880lbs.

Horses = 2,200lbs.

Wagon = 1,000lbs. (is that too high?)

_________________

6,080 lbs. Am I higher than a box kite right now? LOL

Next question: MAYBE THEY NEVER PUT THE HORSES IN WHILE THE HAY WAS IN, AND JUST BACKED THE TRAILER IN? If so, now I'm down to 3,880lbs.

And I believe the L5740 weighs 4,000lb. WITHOUT FEL AND Hoe, right?

What is the weight of an L's FEL? I know the Woods hoe is supposed to be roughly 1,000lb. If the FEL is 800lb. (WAG) then the TLB would weigh 5,800lbs., PLUS up to say, and additional 600lb. in the item being moved.

So, I'm then at 6,400lbs. Nervous yet? I am! LOL

And can a barn that's now dry as a bone, straight as an arrow, etc..., be counted on to have it's original strength?

I honestsly haven't a clue..., so PLEASE CHIME IN ON ANY AND ALL OF THIS STUFF.

The upper floor/lower ceilings joists are 8" hand-adzed beams, on like 3' centers, I believe, and the uprights are UP to 10", hand-adzed.

*Phew!* "Question #1" (and it's dozen, unlabeled sub-parts, is now over--for anyone still reading.:laughing:

2. What is the weight of this L5740 tractor, since I can't find it on Kubota's site. I will be adding a big, Kubota FEL, and a Woods BH80X, which I understand with subframe will be about 1,000 lbs. The stuff I'll be moving will be relatively light, say 200-600lbs. (Parts, antiques, a snowmobile, etc...).

I should explain (if I've done so already, please forgive me--sober, but up two days....) that I don't mind driving around on the second floor, with "watchers" in safe corners, on the (concrete) first floor, with walkie talkies, and I planned to keep the FEL 2" off of the floor, and the hoe's bucket 2" off the floor. That way, I figure I may drop a (front?) wheel through a 16" barn floor plank, which will break my heart, but there IS a lumber yard right down the road, so I would have them roughly simulate the broken plank, round the edges to match it's mates, and then I would weather it outside for a while, then install it (or higher it done, given my injuries).

Or possibly just REPAIR the old plank, with major "sistering" of planks underneath, IF I could gain access to the broken portion. The first floor of the barn is fairly tight, with at least 6 different "rooms," so you can't count on access from the bottom side, necessarily.

But I'd rather not break the floor, and buy TOO HEAVY OF A TRACTOR to begin with.

Sidebar: I Can Hear Your Questions Already--What ELSE WILL You Use the L For?

a) probably snowblowing.

b) possibly mowing, if I can afford the mower--are L's the ones with the "drive over decks"? Because I ain't horsing one in from the side, I can tell you that much.

The property is either under 2 acres or possibly we'll get another 2 acres (please knock on REAL wood for me, THREE TIMES, re: this, as I'm a little OCD--and as you can tell, the treatment ain't working.).

3. How Much Did The Hay Wagons of Back-in-the-Day (post and beam construction, I'm told, dates it to 150-200 years old!) WEIGH?

4. Because this is not a "Grand L5740," does that mean:

a) no tilt wheel?

b) no "quick pin" TPH (or whatever Kubota calls it?)

c) no "Position Control?"

5. It DOES APPEAR have the SUSPENSION SEAT, which I may need, due to recent back surgery (please knock on REAL wood for me, A-GAIN) as I'm nervous about "jinxing" my chances at making a good recovery. THANK YOU VERY MUCH--no, there's no "mental" test required to join TBN, at least none I was aware of--LOL :laughing:

a) Has anyone had any experience with this "suspension seat?"?

b) Is there any "dampening" action to the suspension seat, or is it just "boing-boing" and how effective is it? It SEEMS like a much better deal than just having a hard-mounted seat. I'll have turfs, btw, which should soften the ride further, so I've read.

6. CAN the suspension seat be RETROFITTED into the B3030HDCC, or was it actually offered as an option?

7. How much should I be willing to pay for this tractor, sans back hoe, which I understand will add $7,500-9,000., if I get the Woods?

8. What other differences are there between an L5740 and a GRAND L5740?

Confession: I don't NEED 60 hp. I probably need like 26-30 hp. (might get a snow blower). But this one looked nice, and I like the extra weight for dirt work, etc.... Just not at the expense of breaking my barn--even a floor plank will be extremely painful to me.

9. Can anyone direct me to the portion of Great Plains Kubota's site that USED to allow the side-by-side comparison of specs that I've described? It was SO HELPFUL! In fact, I learned of it from a fellow TBN'er, and was using it only a few months ago!

10. Are L5740's THREE CYLINDERS or FOUR? I remember seeing SOME L's that were three cylinders. The reason I ask is, I HATE vibration, and do NOT want anything to do with the "only affects some units" vibration problems that I've read about with SOME, but not ALL, four cylinder B3000's, B3200's and even, I believe, some B3030's.

11. More importantly, do these L5740's have ANY history of ANNOYING ENGINE VIBRATION PROBLEMS? I've not been in the "L" market before (and probably shouldn't be now, right? LOL) and I've not seen any comments on "L's" having the "vibration issue" of the smaller, four cylinder machines I mentioned.

12. Does the 407 hours bother anyone?

Any "known pattern failures" on these machines I should look for, beyond the normal leaks, wear, bent FEL arms, etc...? Noises?

13. I know tractors don't have "model years," but perhaps an experienced "L" owner could ballpark this machine's age?

14. Of course, now I'll be "married" to the Kubota QA system, when I had planned to buy a B3030HDCC, and have that popular SSQA system (ADI's kit, I believe?) fabbed on by a local fab shop, as my welding is waaaay below that level of quality. But I only forsee the need for GOOD forks and the bucket. Am I overlooking something?

15. What Else Am I Possibly Overlooking, Generally?

Hit me--I can take it--I'm not big physically, but I've got a strong heart, so lemme have it, please.

16. Bent FEL Arms? In the top row's FAR RIGHT thumbnail, it looks like the left front corner of the bucket is "flying." I believe this used Kubota dealers has a new shop (with hopefully a flat floor) so I could check tire pressures, and try to determine if something is bent.

a) Any better way to do this? I was thinking of buying some 12' 1" x 4"''s, and a looong level, just to check his floor, but let's say it is tweaked. I've got OCD, so that WILL bother me, but:

b) Is it more of a negotiating point, or would you guys run, if the FEL is twisted? IF it's twisted, how much off his "final price" would you lean on him for--$500.? $1,000? More?

17. The problem, again, is the barn planks. I've been told I could cover them all with 1" plywood or even particle board, and VASTLY increase their load-bearing ability. Opinions? My "bugaboo" about that is, I WANT to see those barn planks. And I don't want to buy, then screw together, 20-30 sheets of anything that's 1" thick.

And Now, a Favor: For those so inclined, I would appreciate, for clarity's sake, that if you take on one of my questions, you'd be so kind as to refer to it by it's number(i.e., 1-17 or whatever I'm up to), as I know this is a long, rambling "My Hoe" post, and I'm sure OTHERS would appreciate the quick reference to my question numbers just as much as I would.

If this doesn't get me kicked out of the TBN'ers' club, then you guys are EVEN KINDER and MORE GENEROUS than I already knew you to be.

Thanks again,

My Hoe

Attachments

-

10 Inch Beam Downstairs in Barn.jpg1,000.6 KB · Views: 266

10 Inch Beam Downstairs in Barn.jpg1,000.6 KB · Views: 266 -

General, 3' On Center, First Floor, 8 inch Floor Joists.jpg1,010.8 KB · Views: 210

General, 3' On Center, First Floor, 8 inch Floor Joists.jpg1,010.8 KB · Views: 210 -

Sistering for 3,000lb. Muscle Car.jpg989.8 KB · Views: 314

Sistering for 3,000lb. Muscle Car.jpg989.8 KB · Views: 314 -

Downstairs, Livestock Area--Brick Wall.jpg1,001.5 KB · Views: 243

Downstairs, Livestock Area--Brick Wall.jpg1,001.5 KB · Views: 243 -

Torture Chamber.jpg846.8 KB · Views: 318

Torture Chamber.jpg846.8 KB · Views: 318

Last edited: