J252

New member

*** I will return to this thread and fill in this post with a great more details as I get the chance.***

For now, you can watch this Youtube video and read the extended description.

Kubota L3400 - 3PH Action @ 2000 RPM - YouTube

Quick summary:

L3400 with extremely jerky 3PH (violent) with old YR909-00100 PCV. We bought the tractor used this winter, and were quickly and thoroughly disgusted by this fundamental problem. I dismantled and studied the PCV system and made the mods early this spring. Have been using the tractor like this all summer and am very happy with the result.

1. Disassembled the PCV and chamfered the spool control edges by ~200 um. This increased PCV response and reduced the violent jumps from 1" down to less than 1/4".

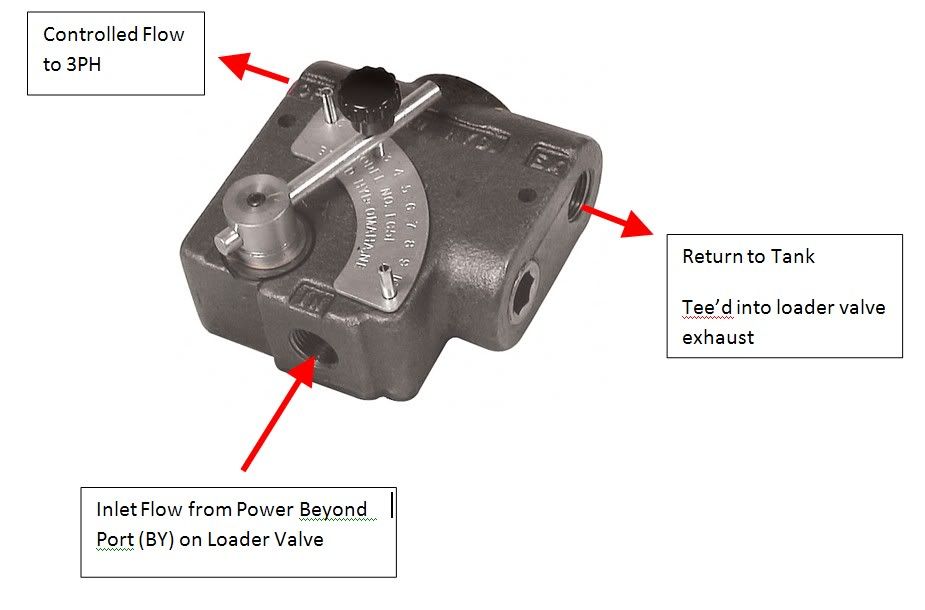

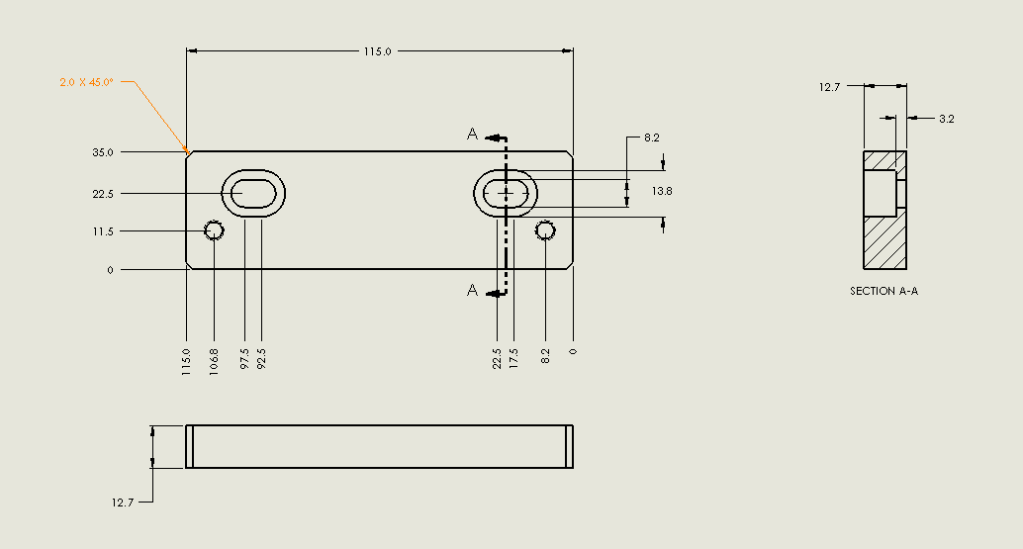

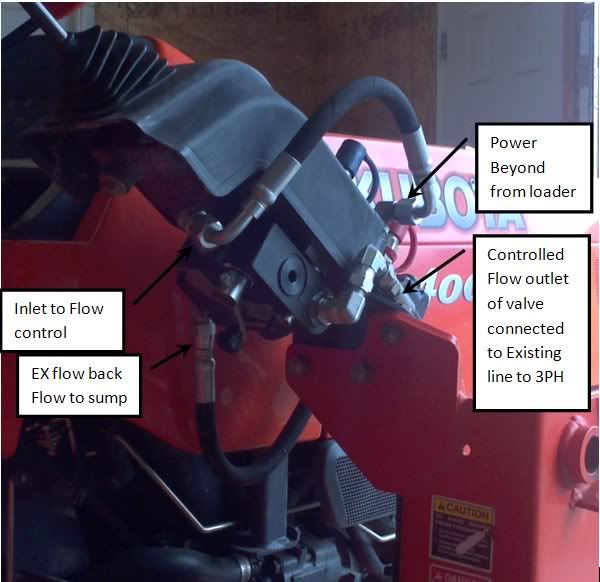

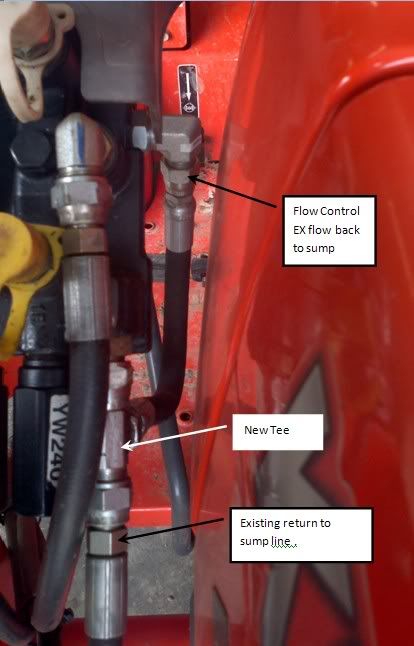

2. Added an external pressure compensated flow control valve ($~90 + lines and fittings). This reduced the flow to the 3PH system and took the violence out of the 3PH motion. It also reduced the lift speed though this is now adjustable. It did not affect the 3PH lift capacity or the FEL in any way.

I will fill in the blanks, and explain much more thoroughly later as well as show photo's and a part list of the install.

Cheers,

Jeff

For now, you can watch this Youtube video and read the extended description.

Kubota L3400 - 3PH Action @ 2000 RPM - YouTube

Quick summary:

L3400 with extremely jerky 3PH (violent) with old YR909-00100 PCV. We bought the tractor used this winter, and were quickly and thoroughly disgusted by this fundamental problem. I dismantled and studied the PCV system and made the mods early this spring. Have been using the tractor like this all summer and am very happy with the result.

1. Disassembled the PCV and chamfered the spool control edges by ~200 um. This increased PCV response and reduced the violent jumps from 1" down to less than 1/4".

2. Added an external pressure compensated flow control valve ($~90 + lines and fittings). This reduced the flow to the 3PH system and took the violence out of the 3PH motion. It also reduced the lift speed though this is now adjustable. It did not affect the 3PH lift capacity or the FEL in any way.

I will fill in the blanks, and explain much more thoroughly later as well as show photo's and a part list of the install.

Cheers,

Jeff

Last edited: