Hi all,

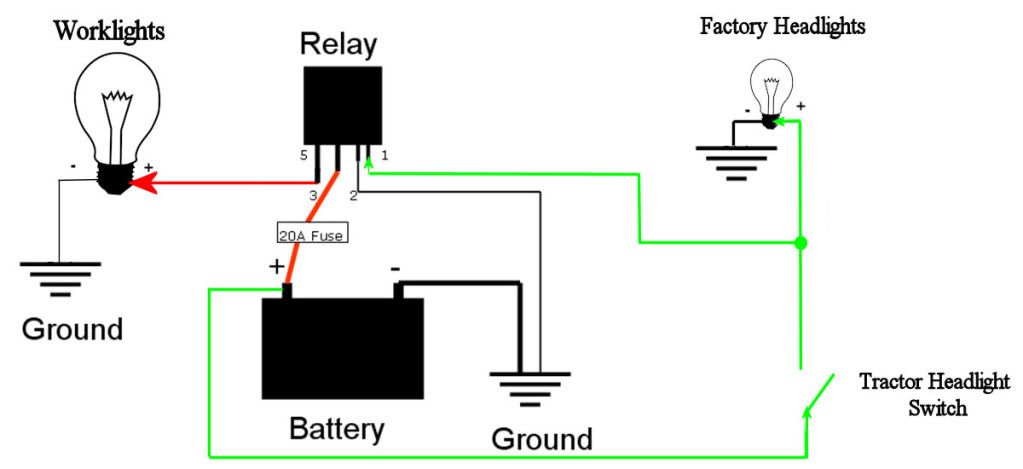

I want to add a work light to my BX25 Rops. I have read most of the things written on mounting work lights and there has been some great ideas. I see that alot of people put in switches, but I have not read anywhere about just tapping in to the head light wire. That way when you turn your headlights on the work lights come on as well.

thanks

I want to add a work light to my BX25 Rops. I have read most of the things written on mounting work lights and there has been some great ideas. I see that alot of people put in switches, but I have not read anywhere about just tapping in to the head light wire. That way when you turn your headlights on the work lights come on as well.

thanks