cschulz

Gold Member

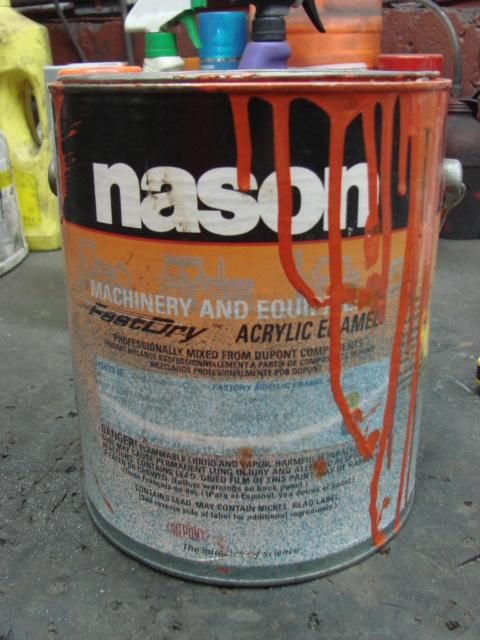

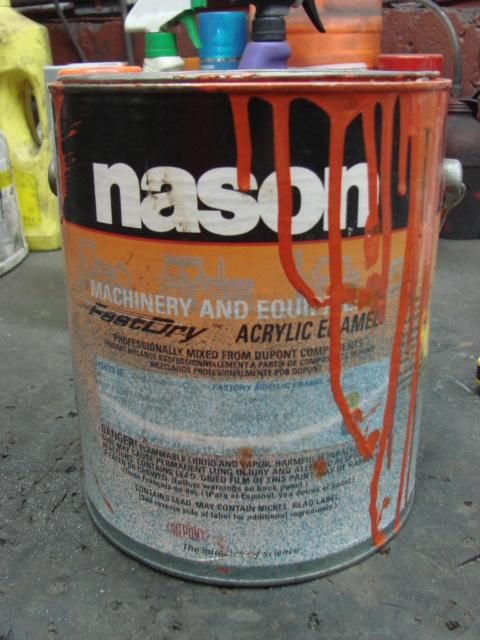

Hey Paul, Ive seen that you mentioned using Machinery Enamel in another posting for paint. Do you purchase from a automotive paint supplier? And do you use reducer or hardeners? Is the color off the shelf or custom tint? Thanks I really needed to find a better way to add tough paint to my tractor parts.

Chris

Chris