Man I don't know. There are hundreds of these BX tractors out there with wheel spacers installed on them mine included that haven't had an issue. Actually yours is the only one that developed a crack that I know of and where a wheel spacer was mentioned in the same sentence. Maybe you just had a bad casting? Maybe something else? I realize that you said you don't know if the wheel spacers were a direct cause of your problem but when you mention nuclear inspector and saying the crack appeared two months later you sure are insinuating they were the cause when in actual fact you have very little evidence that the spacers had anything to do with it at all. :confused3:

I've hauled at least 12 tandem loads of heavy gravel with my BX at long distances and never had an issue. If the spacers were going to cause a crack they sure would have done it on my job. (See photos)

Now I appreciate the fact that you are a Nuclear inspector and I am a licensed vehicle inspector and in my opinion the wheel spacer had nothing to do with it.

Remember, this is someone's lively hood and good reputation here we are dealing with. I think you should have had more definitive evidence before dragging Bro-Teks good reputation through the mud.

I'm running 1.25" front and 2" rears.

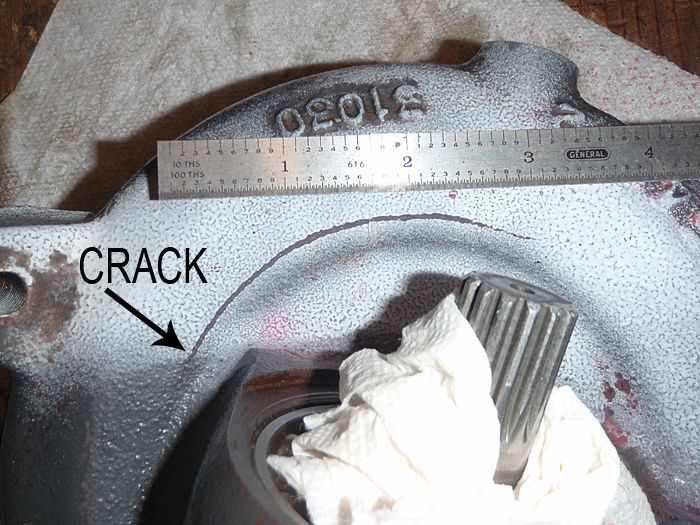

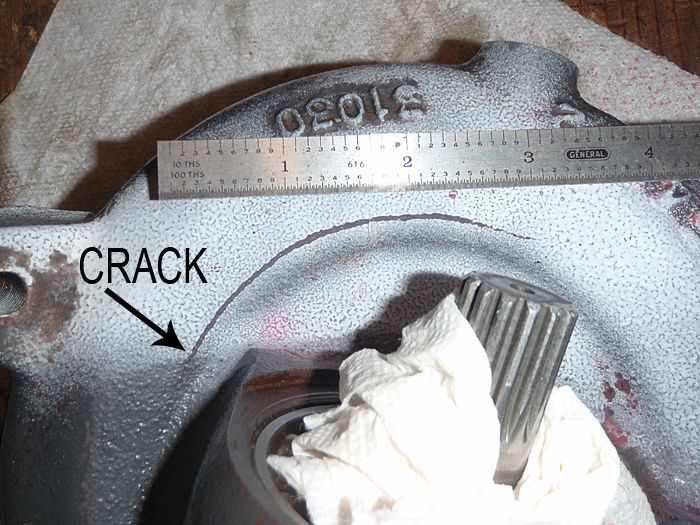

I posted this in an effort to make others aware of the potential failure and only stated the facts of the inspection, duration, usage, and changes made. how you interpret that is up to you. I stand behind 28 years of inspection, identifying and determining how the failure may have originated, those range from thermal fatigue, stress corrosion, fatigue, cyclic stress or inherent. Do to the nuclear safety involved it is not only imperative to identify it, but to identify the root cause.

That can be done by knowing parameters of use, temperatures, stresses, and possible inherent discontinuities with in the material, as well as various inspection techniques used to identify the indication, many times requiring a long paper trail.

While you show your tractor being used on a somewhat level grade in an urban environment, my unit is used in an undeveloped area in an effort to establish access, consisting of side hills, and uneven terrain to shuttle stones to the job sight. This reflected in uneven lateral loads being placed on the front axle assembly. Whether those stresses acted on an inherent casting flaw is anyone guess without a paper trail to identify if they where ever inspected, we can continue to assume that they where most likely not. However, the use of the extension would place additional leverage to the same area of the indication due to the bevel gear hub design.

Which takes us back to my first sentence "I posted this in an effort to make others aware of the potential failure and only stated the facts of the inspection, duration, usage, and changes made".

Much the same as one pointing out it could be a coincidence that it failed after installing the extensions..

I merely stated the facts based on my expertise, knowledge, and training.

Rich turns out quality stuff and I do not aim to discredit him, I personally performed a visual inspection on all the items I received from him, belly pan, thumb, claw for thumb, brush forks, and the extensions. The quality of craftsmanship is first rate, welds are comparable to that of what I am accustom to seeing in a power plant.

None the less, I felt it important to share with others if in deed it becomes more evident with other kubotas, or those using extensions. I don't aim nor ever have to drag ones good name through the mud, only create the speculation that it could have been and let the end user decide for themselves based from the facts stated here.

~Tol