Re: Upsized Hydraulic Clyinders for Loaders (Attached drawings)

Your accumulator sounds like the accusatory that is the basis of the Kubota Ride System (KRS) on large Ag tractors. It really softens the bumps when gathering up large round bales. Increasing curl force that loads your axle - I'm trying to understand the load condition. My L5740 is extremely weak in curl when having the bucket curled completely flown and try to push myself out of the hole in which I'm stuck. Major difference between this and the L3710 I traded in. The problem here is mechanical advantage - almost zero in straightening the bucket after its tilted completely. The Grand L front axle is weak, especially in bearings judging by the info I found when I failed the LH side bearings on mine at about 600 hours. My dealer said one customer has the system down - he pulls both fronts when one side fails and takes them to the dealer to repair because the other side is always likely to go soon. So which curl load is hard on the axle? When I curl in the bank I think I am just rotating the bucket around the rear corner do the axle is not getting extra load; however, I could get a more full bucket which would hurt it.

I believe construction full size TLB's have a system as a option Similar to the Kubota Ride System (KRS).

Regarding increasing the curl force, this can put a lot of strain on the front axle. The best way to avoid is as yon mention, go in with the bucket a little high and bury the bucket in the pile as best you can in rear wheel drive.

Then curl the bucket back, while not Lifting or driving forward aggressively.

The works thing you can do to the front axle, aside from hitting a loaded tractor with an excavator, is to be in 4Wd, bucket under a stump, etc. driving hard forward and lifting an curling at the same time. The little bevel gears in the front axle are torque aversive, along with the spindles and just about every other component, including the steering. If your doing this with the edge of the bucket you may also rack the loader.

I suspect tractors are designed with weak loaders for safety during operation, and protection against abusive use.

Me, i respect a machine that can hurt itself with a little help.

On a well designed tractor, the safety factor has to be huge to give the tractor a degree of idiot resistance. The world is growing better more advance idiots on an exponential scale, so lots of bad stuff is going to happen.

Regarding your L5740 that like the Kubota Construction TLB´s and many better designed loaders the bucket linkage has 4 pivots, vs. 2 so as to get a getter amount of dump and curl back angle. At the extremes of motion, that type of linkage has very little leverage.

But wait, there's more!

Your L5740 has a regeneration circuit on the dump cycle. During dump full pressure is applied to the extend and retract ports,. Motion occurs due to the area difference of the rod, speeding up the dump cycle.

Some loader control valves have the flow dump back to supply tank ant the beginning of the jioystick movement to dump, then go regen.

A suspect that Kubota's are 100% regen.

GrandL's crap front bearings and seals just because the are not that beefy. Knock on wood, my front axle is not leaking after +500 hours since the repair. I think there are several seal kit versions Kubota has cycled thru over times

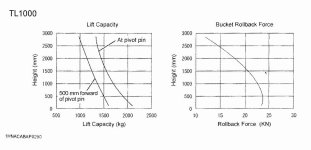

Carefully moving heavy pallets and rocks with my pallet forks is where I want the extra curl and lift as from the photo's below, execpt in hard digging, the L39 is adequate. I try to be as gentle a front axle abuser as possible.

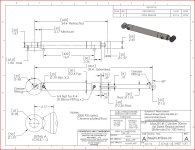

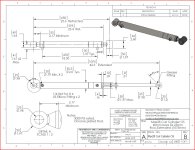

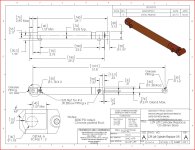

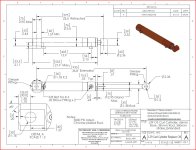

Attacthed are my resized cylinder drawings.