BoneheadNW

Gold Member

I was greasing my FEL (LA352) when the grease gun got stuck on the zerk. After some twisting I got it loose but ended up breaking the zerk off in half. After a trip to the auto parts store for more zerks and a set of easy outs, I tried to get the broken half of the zerk out but have been unsuccessful so far. The easy out just seems to be shredding the zerk from the inside- I'm sure the fact that the thing is coated with grease doesn't help.

Thus, I have two questions:

1. Does anyone have any suggestions on how to remove the half of the zerk stuck in the threads?

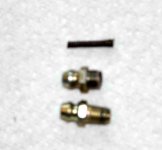

2. I found a very thin spring lying on the ground and believe that it came from behind the broken zerk (see photo). Does anyone know about this? The zerk is from the fitting just behind the bucket, if that makes a difference.

Note in the picture the broken zerk is just below the spring, the new zerk is on the bottom.

Thanks,

Bonehead

P.S. Sorry for the blurred photo- I didn't want to get grease on the camera!

Thus, I have two questions:

1. Does anyone have any suggestions on how to remove the half of the zerk stuck in the threads?

2. I found a very thin spring lying on the ground and believe that it came from behind the broken zerk (see photo). Does anyone know about this? The zerk is from the fitting just behind the bucket, if that makes a difference.

Note in the picture the broken zerk is just below the spring, the new zerk is on the bottom.

Thanks,

Bonehead

P.S. Sorry for the blurred photo- I didn't want to get grease on the camera!