You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bradco ground shark

- Thread starter 05rammer

- Start date

/ bradco ground shark

#1

powerstroke01

New member

- Joined

- Jul 12, 2014

- Messages

- 7

- Location

- thompson, ohio

- Tractor

- 2007 ASV SR80 track loader , Swinger 2000 articulated loader

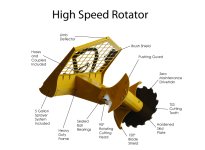

First off, this is the first time I've ever posted to a forum. I'm usually "lurking in the shadows", but I felt the need to give my two cents worth. I run an ASV SR80 with a high flow Bradco Ground Shark. I also have the stump grinder teeth option. This is the only brush hog to own, In my opinion. The only attachment more productive on heavy wood would be a forestry head. Advantages of this beast: it can process 6" softwood all day, grind the stump down to grade, grind/ mulch brush piles, has oil pressure gauge standard, and the largest bearing assembly I have seen on any brush hog. Disadvantages: extremely heavy at 2008 pounds, a little pricey (I paid $10,000), blade and stump teeth are expensive to maintain/replace. The replacement knives (4) from any dealer cost $1200.00. Absolutely ridiculous, but with some serious searching I found a machine shop that sells them for $80.00 each. Same thing with the stump teeth (18), dealer wanted $400.00. I found teeth for $7.35 a piece. On two to three year growth, it leaves a lot of stems still standing, but then again this isn't made to cut grass. Please ask any other questions. There doesn't seem to be a great deal of information about this model out there to ask people about.

I own a groundshark and when the blades got wore enough I took then to a welding shop and had then build them back up and put an edge back on --of the four only one was 2 more ounces than the others- I ground off the two ounces. the renewed edges are lasting as well as orginal.

lumberjack1986

Silver Member

How does it do on hardwoods? I'm wanting to buy one for my SVL90-2.

Care to post up or PM your contact for the cheaper blades? I agree the blades are way over priced, the stump teeth are marginally so.

Care to post up or PM your contact for the cheaper blades? I agree the blades are way over priced, the stump teeth are marginally so.

powerstroke01

New member

- Joined

- Jul 12, 2014

- Messages

- 7

- Location

- thompson, ohio

- Tractor

- 2007 ASV SR80 track loader , Swinger 2000 articulated loader

I would say if your mowing Ash, Oak or Sugar Maple etc. your productive up to 4-5" in stem diameter. In softwood like Aspen, Buckthorn, Sassafras etc. you can cut and mulch around 8" material. Even with the stump grinder teeth on the disc, your still going to have arm sized pieces of wood from the trunk section of the tree, unless of course you have a lot patience! I found replacement blades from Lewis Machine Company in Clanton Alabama 1-800-545-4343. Their website is lewismachine.com/. Blades and shipping were just under $400.00. When you call down there, tell them there for the Bradco. I was the first customer to try them, because they are actually replacement Davco blades. The Bradco uses 3/4" material for the blades, but the Davco blades are only 5/8". They work fine, but my next order I'm going to see if they can make me 2 sets out 3/4" material. The part number is LT-732 Davco SS 705 blade 5/8" x 8" x 18". The stump grinder teeth came from Huron Quality Manufacturing in Lincoln Michigan. Their website is discountstumpcutters.com. Phone number is 1-888-467-8867. The stump grinder teeth cost $7.35 each. If any one has any other questions, feel free to ask!

ShowroomShine

Gold Member

I sell them at work, customers love them.

Also look at Blue Diamond. I forget the model right now (its been a long night and beer is involved), but they also have a skid mounted shredder option.

Also look at Blue Diamond. I forget the model right now (its been a long night and beer is involved), but they also have a skid mounted shredder option.

marshalldougherty

New member

If you're trying to cut with carbide teeth and get below the ground I'd recommend the Turbo Saw. It's made by DFM and they've been doing it for over a decade. They have a hydraulically rotating head that can trim limbs as well as cut down 30" trees with a 10" a second cutting rate. There carbide teeth are rated to work in dirt or sand and they last over 200 hours.

Attachments

lumberjack1986

Silver Member

God you spam everywhere.

I got my Ground Shark in yesterday, it's a beast!

Here's a decent sized gum, took 4 minutes to cut and process it.

Didn't time these, but still, it does great!

Here was the biggest hickory I took down. Size 14 boot makes that a 16" stump, roughly. This tree took 16 minutes to process. The blades were dull going into this tree, I'm curious how much difference that will make.

Powerstroke, I sent Lewis Machine an email asking about 3/4" blades. I will let you know what the response is. Thanks for posting the information!

I got my Ground Shark in yesterday, it's a beast!

Here's a decent sized gum, took 4 minutes to cut and process it.

Didn't time these, but still, it does great!

Here was the biggest hickory I took down. Size 14 boot makes that a 16" stump, roughly. This tree took 16 minutes to process. The blades were dull going into this tree, I'm curious how much difference that will make.

Powerstroke, I sent Lewis Machine an email asking about 3/4" blades. I will let you know what the response is. Thanks for posting the information!

powerstroke01

New member

- Joined

- Jul 12, 2014

- Messages

- 7

- Location

- thompson, ohio

- Tractor

- 2007 ASV SR80 track loader , Swinger 2000 articulated loader

No problem about the aftermarket info. I'm curious to see if Lewis Machine has any problem making any blades out of 3/4" material while set up for their normal batches. I actually want them to also carry the bevel all the way across the blade, that way I can sharpen them on my automated knife grinder.