Ok,

I hope I am posting in the right location.

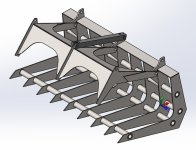

View attachment 499145

So i finally got my design moving along and I was thinking you guys could help make any necessary changes while it's still in the design stage.

Any and all comments would be appreciated.

The grapple will be 50" long and have an opening of right at 40", I have my tines spaced at right at 9" to help keep the weight down.

I am putting it my Mahindra 2538HST.

Any advice is appreciated.

Thanks

I have a couple thoughts.

1. Can you show the SS adapter on the back of the grapple? It appears there may be extra material on the lower corner that is not required for strength. It may be required for the height of the adapter however.

2. If you are cutting the holes for weight savings, I would consider making them a bit larger, or not bother with the holes. The current size shown will not result in significant weight savings.

3. Consider angling the back of the grapple further forward. Assuming your SS adapter on the tractor is vertical when rolled fully back, some additional angle might be helpful with getting material to fall back into the bucket. This, of course, will depend on your uses for it. For some purposes, this would be a disadvantage.

4. What thickness are your tines? I would seriously consider using Hardox vs mild steel, and using thinner tines. If you have never used Hardox, it is amazing stuff. The cost difference is probably worth the impressive weight savings you will see by going to thinner material. For reference, mild steel is around 50k psi yield strength, Hardox 450 is around 175k psi. You could go with 1/4" tines easily.

5. I would use larger pipe for the cross bracing. I think you will bend the smaller ones shown.

6. If you are using it for placing rocks in stone walls, it may be helpful to have the edge of the jaw closer to the edge of the bucket so you can lift and place using the corner of the bucket/jaw. For brush, this is insignificant.

7. For bushings, I like to use grade 8 lock washers along with a drilled hole in the material. They fit tight to the pin generally. I cut opposite the factory cut with a die grinder, almost all the way through so they lay flat. Then run a bead around the edge. Not replaceable obviously, but I doubt that's an issue for this application.

8. For third function, I have the WR long kit on mine. I like having the switch on the loader handle. Some people just run off the rear remote, it's a cheaper option if you don't mind the ergonomics.

What weight is your model currently? It looks similar to the model of the grapple I plan to build one of these days. My design is not quite as far along as yours is however. I need to flesh out the details. It is currently around 350 pounds for a 5 footer, with a clamp force of a few thousand pounds. Are you using Solidworks? Have you done any structural analysis on it?