linuxman51

Gold Member

- Joined

- Nov 26, 2012

- Messages

- 300

- Location

- Montgomery, AL

- Tractor

- craftsman lt1000/jd 717a/ mahindra max26 hst

Well, almost 2 years, it was picked up in july '15 after my max 28 was stolen from the dealership.

I have to say, I miss my 28. I was a relatively early adoptee, picking the 28 up in 2012, I understand there were some running changes that bring the differences between the 28 and the 26 to virtually nothing by 2014-15, but it just seems... weaker, and more problem prone (now, to be fair, some of the problems I encountered with the 26 would have likely also been encountered with the 28, clearing brush tends to knock things loose and has the potential to occasionally punch a hole/knock a hose loose in the relatively soft underbelly region), but also having some nice touches to go along with it. cup holder, nice. mounts for the 3pt hitch stuff on the backhoe, also nice.

loader.. seems more 'meh'. backhoe seems to be a bit more lacking as well (or, maybe I've just gotten used to it). Still hate the **** out of that stupid seat, at this point it's falling apart.. the ball locks don't stay put. Not sure how I'm going to address that yet. Discovered this weekend that I'd somehow managed to bend the left (looking at the rear) outer "ear" for the lower link on the 3pt.. I haven't had anything on the 3pt with any kind of load in months and the last thing I did use was the phd.. wasn't bent then, no clue what happened there but it must have been pretty impressive.

the subframe for the backhoe routinely snags the lower links depending on what's attached at the back (the box and the tiller...esp the tiller), thats.. awesome.

But it's not all bad, beats the heck out of doing work with a shovel, in spite of the aforementioned misgivings, it is still a workhorse that starts every time, nothing major mechanical has failed (Although, looking around at some other posts, apparently I need to take a closer look at things). Reckon it's one of those things.. the first one is always the best one :laughing:

I still wouldn't trade it thought, it's a fantastic tool to have available.. adding the toothbar to the fel bucket along with a piece of angle to reinforce the top edge, and fabbing a skid plate with side pods to protect the underside has cut way down on the number of field-stoppages resultant from occasional brush clearing (as well as a reduction in hydraulic fluid usage). All in all, growing pains that didn't happen with the 28 (it saved it's problems for one big shot at the 3 year mark), and what feels like a little more lacklustre performance, but still a great machine. If you can get past that **** seat.

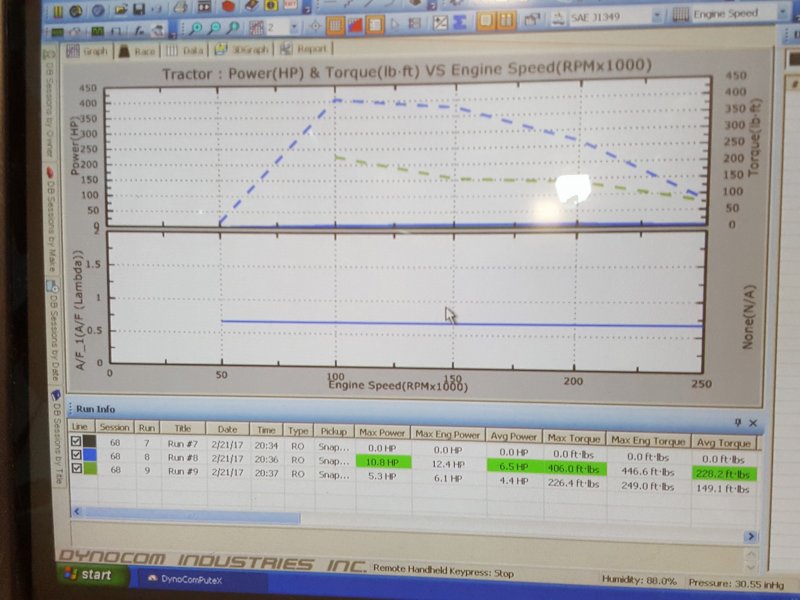

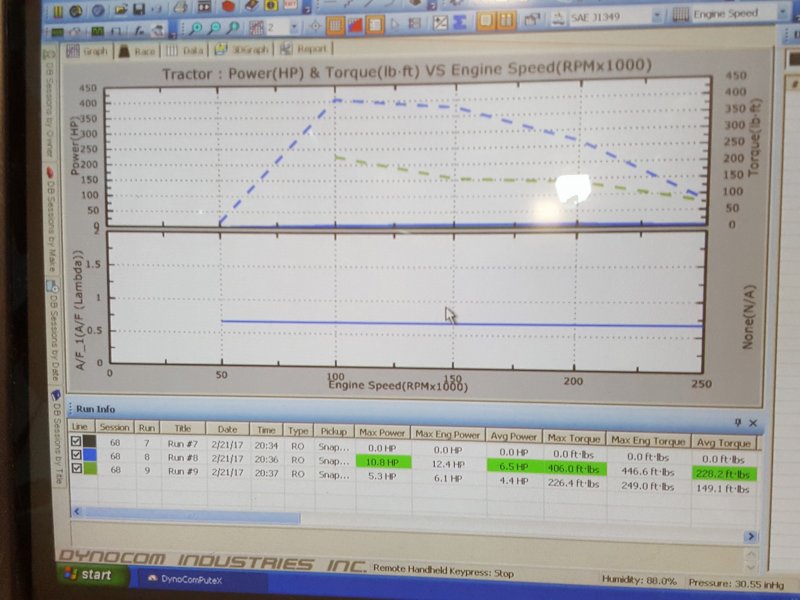

oh and if anyone is curious, you can get some interesting dyno readings from a tractor:

I have to say, I miss my 28. I was a relatively early adoptee, picking the 28 up in 2012, I understand there were some running changes that bring the differences between the 28 and the 26 to virtually nothing by 2014-15, but it just seems... weaker, and more problem prone (now, to be fair, some of the problems I encountered with the 26 would have likely also been encountered with the 28, clearing brush tends to knock things loose and has the potential to occasionally punch a hole/knock a hose loose in the relatively soft underbelly region), but also having some nice touches to go along with it. cup holder, nice. mounts for the 3pt hitch stuff on the backhoe, also nice.

loader.. seems more 'meh'. backhoe seems to be a bit more lacking as well (or, maybe I've just gotten used to it). Still hate the **** out of that stupid seat, at this point it's falling apart.. the ball locks don't stay put. Not sure how I'm going to address that yet. Discovered this weekend that I'd somehow managed to bend the left (looking at the rear) outer "ear" for the lower link on the 3pt.. I haven't had anything on the 3pt with any kind of load in months and the last thing I did use was the phd.. wasn't bent then, no clue what happened there but it must have been pretty impressive.

the subframe for the backhoe routinely snags the lower links depending on what's attached at the back (the box and the tiller...esp the tiller), thats.. awesome.

But it's not all bad, beats the heck out of doing work with a shovel, in spite of the aforementioned misgivings, it is still a workhorse that starts every time, nothing major mechanical has failed (Although, looking around at some other posts, apparently I need to take a closer look at things). Reckon it's one of those things.. the first one is always the best one :laughing:

I still wouldn't trade it thought, it's a fantastic tool to have available.. adding the toothbar to the fel bucket along with a piece of angle to reinforce the top edge, and fabbing a skid plate with side pods to protect the underside has cut way down on the number of field-stoppages resultant from occasional brush clearing (as well as a reduction in hydraulic fluid usage). All in all, growing pains that didn't happen with the 28 (it saved it's problems for one big shot at the 3 year mark), and what feels like a little more lacklustre performance, but still a great machine. If you can get past that **** seat.

oh and if anyone is curious, you can get some interesting dyno readings from a tractor: