dbotos

Silver Member

This weekend while washing the tractor, I noticed some oil / oily dirt inside the left rear wheel. I checked it again today and there was some more fresh oil there (see attached pic). Assuming it's a seal and will need to remove the wheel to get at it. Would also like to check the brakes while I'm in there.

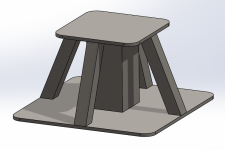

So how does everyone lift / support their 20/30/35 for wheel removal? I measured about 23" from the dirt up to the bottom of the axle tubes and about 17" up to the bottom of the differential. I've got a bottle jack, a farm jack, floor jack, two pairs of regular car/truck height jack stands, and a good pair of steel wheel chocks. Perhaps make some heavy-duty truncated-pyramid risers for the bottle jack and stands? I saw this video on the Ferguson three-point jack, which is pretty slick, but it looks like that might take a little more time to fabricate:

Ferguson Tractor Jack - YouTube

Harbor Freight also has these big jack stands that go up to about 30", which would save me from having to make risers for my current ones:

12 Ton Jack Stands

Tempted to use a 20% off coupon on a set of those. Just don't let my wife see me bring home another free flashlight or screwdriver set.

So how does everyone lift / support their 20/30/35 for wheel removal? I measured about 23" from the dirt up to the bottom of the axle tubes and about 17" up to the bottom of the differential. I've got a bottle jack, a farm jack, floor jack, two pairs of regular car/truck height jack stands, and a good pair of steel wheel chocks. Perhaps make some heavy-duty truncated-pyramid risers for the bottle jack and stands? I saw this video on the Ferguson three-point jack, which is pretty slick, but it looks like that might take a little more time to fabricate:

Ferguson Tractor Jack - YouTube

Harbor Freight also has these big jack stands that go up to about 30", which would save me from having to make risers for my current ones:

12 Ton Jack Stands

Tempted to use a 20% off coupon on a set of those. Just don't let my wife see me bring home another free flashlight or screwdriver set.