Hi Shaeff, good to see you're back on deck.

I've been a bit quiet recently, busy outside of an afternoon now that it's summer. Was reading the thread and as the idea was forming in my mind I read GaryLock's post describing a similar point. He could be right - the lift arms might just be one spline out on the rocker shaft. Your comment about the RH levelling box touching the axle housing when fully lowered is not abnormal - same on both my tractors and all similar models I've seen. I've never learnt exactly how the control side of the hydraulics actually works, so I'm quite puzzled how you can actually get it to work again from inside the lower housing. It sounds like something travels a little too far once fully lowered, and can no longer reach the linkage to move the control valve toward the "raise" direction. Lifting the arms only moves the mechanical components after the hydraulic cylinder, not the piston itself. Manually moving the valve (or the linkage to it) gets it back within working reach.

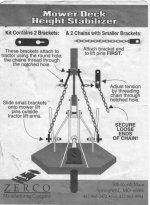

For the short term at least, moving the arms one spline might lose you a little lifting height, but get it to do what you want. :thumbsup: Alternatively, Coldsteelva's suggestion of a stop (even a small block of hardwood timber strapped to the axle housing) or your idea of travel-limiting chains will also achieve this. Be careful to ensure you use the triple-eyes on the rear housing, never the top link mount on these tractors - they can't handle much vertical or lateral force at all, only longtitudinal loads.

I'm going to have to fix my good friend's 35 hydraulics soon, so that could be rather enlightening! :laughing: