Time for the pistons to be installed along with the connecting rods first I cleaned the

With mineral spirits

All nice and clean

Some assembly lube lube every moving part you can these are where the wrist pin goes through in the piston and that's why holds the piston to the connecting rod

Not all pistons have this mark but these do th mark should point to the front of the motor factory pistons have a notch that point forward depends on who makes the pistons it does matter which way they go in

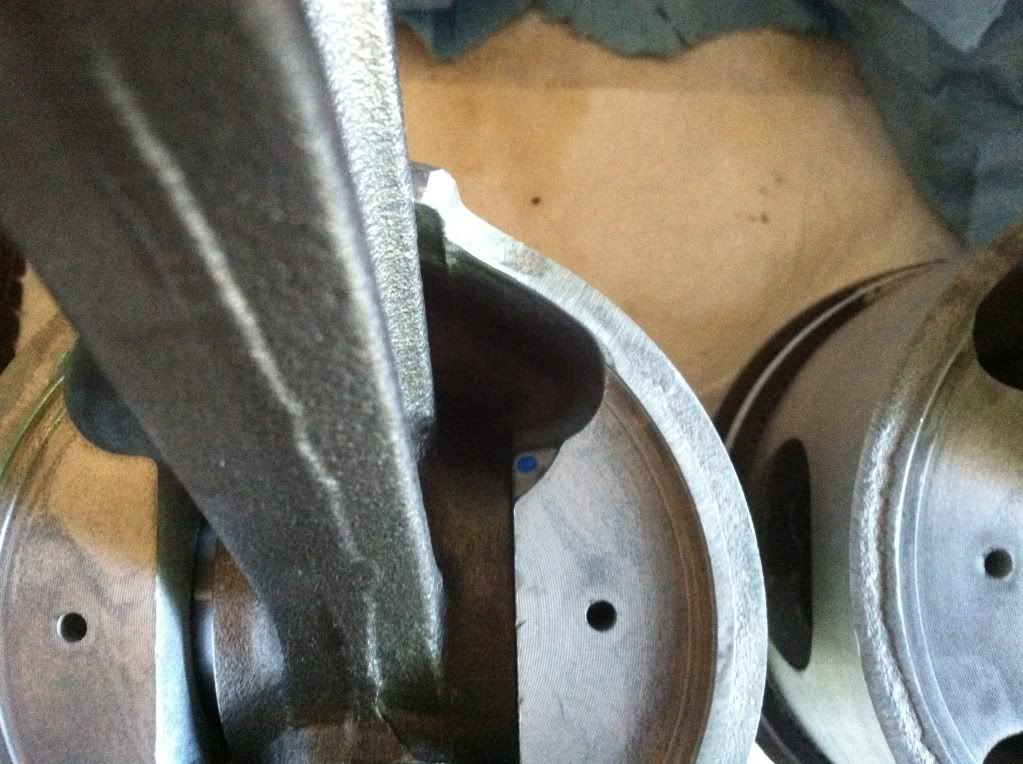

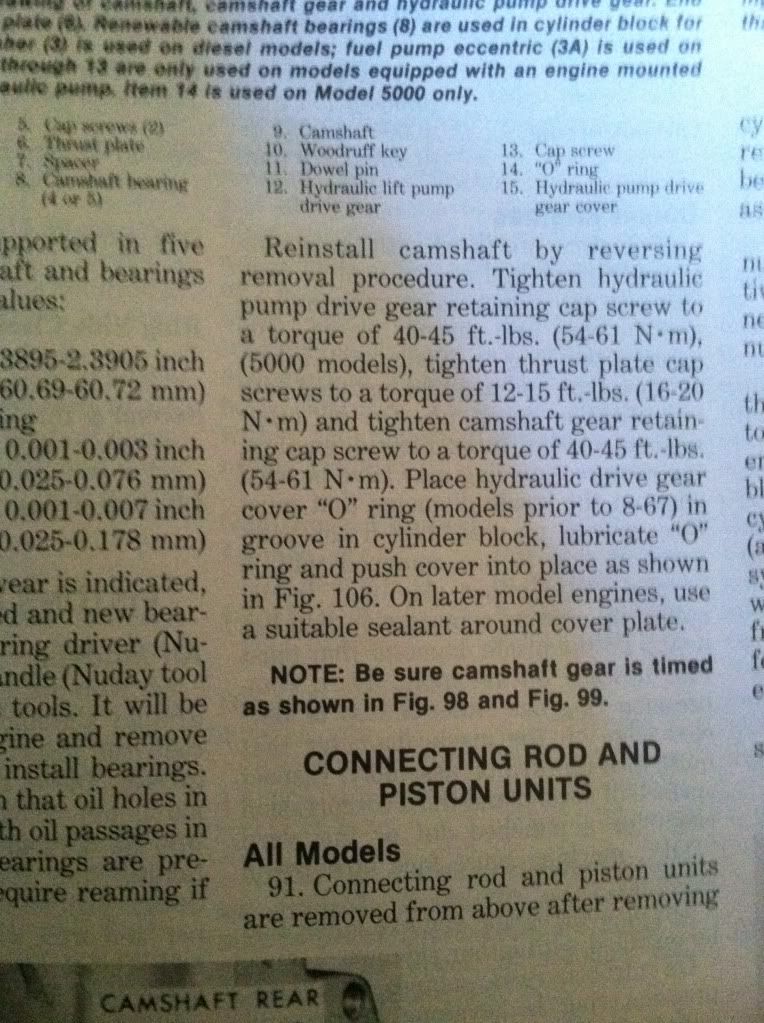

Also note the numbers on the connecting rods. when rods are taken apart numbers should be lined up same side like this picture. also when the rod is put on the crank shaft These numbers should point to the camshaft no clue why always have been taught that way. Must be because of the direction the bearings lock in.

Piston size numbers my number pointe to the front of the block

This is exactly how the piston will go in the rod numbers were pointing towards me the front of the motor is to the left in this picture

All assembled make sure you lube your wrist pins too

Notice the notch on mine they point to the front of the motor

All connecting rods numbers are towards me the notch is opposite

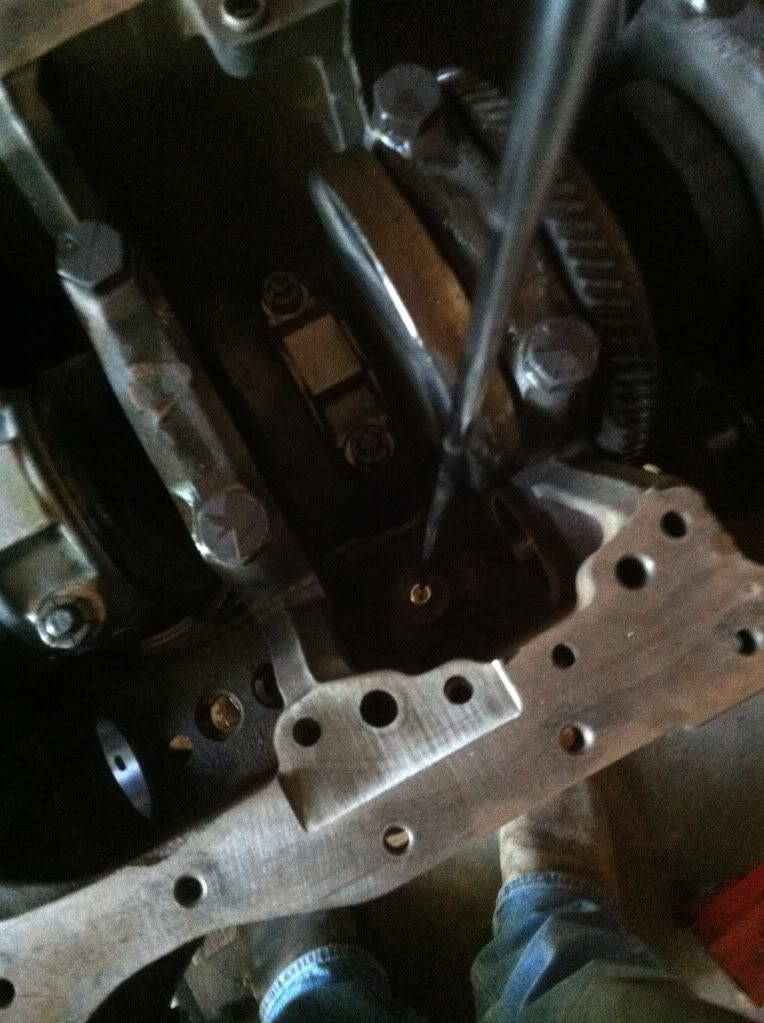

Installing all the bearings make sure they are nice and clean also be very careful not to knock them

Next make sure cylinder walls are very clean no hoaning material should be left from the machine shop after its clean clean again with a white rag then oil down the cylinders walls and you'll be ready to Install your pistons

Next it's time to oil your piston rings for the initial start up line all end gaps and poor oil in the then walk the ring all around one by one till they all feel lubricated

Then it's time fore assembly lube on your bearing for your connecting rods because its almost time to install them after the tops and bottoms are lubed

Next slowly drop your pistone in and crank your crankshaft over so the journal is at top dead center or at its up most position. VERY IMORTANT line your rings up at opposite sides closest ring to your wrist pin which is your oil ring should be lined up to your wrist pin next ring up is a compression ring should line up to the skirt to the left or right then the third from bottom should be lined to the opposite skirt side the fourth should be lined up with the wrist pin on the opposite side of the first one.

Now time for the ring compressor tighten it up and piston install time athen just simply bump it in with the handle of a hammer make positive cylinder walls are lubed good

Nice and installed front of my motor is to my right now

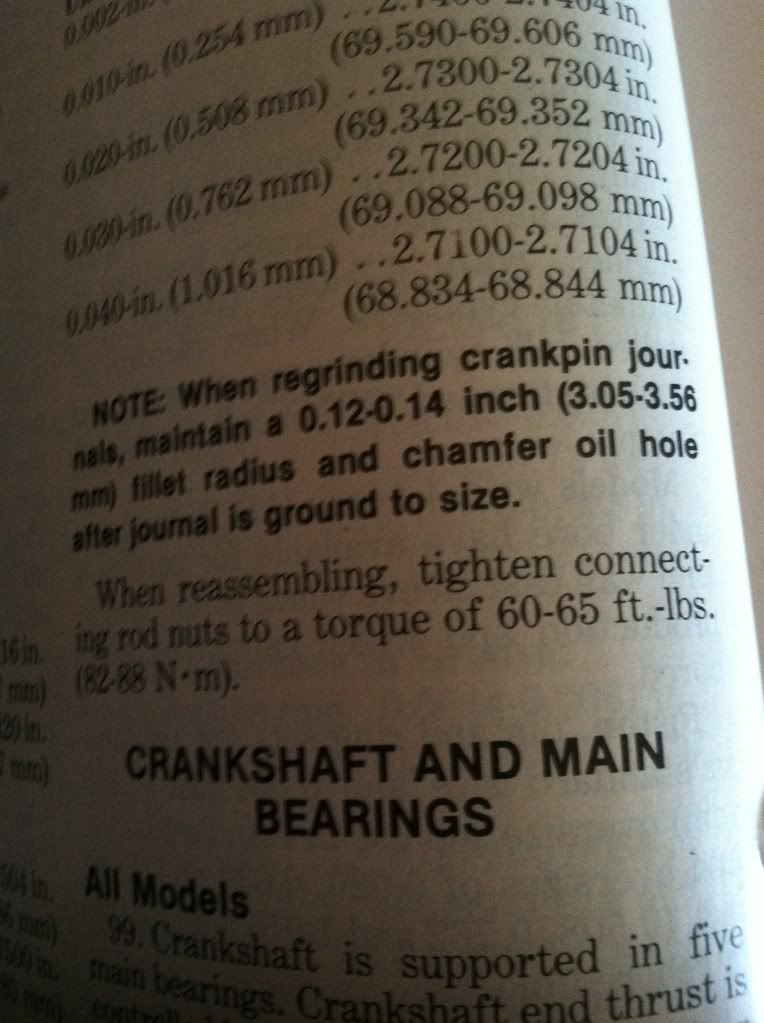

Connecting rods torque settings