Russell,

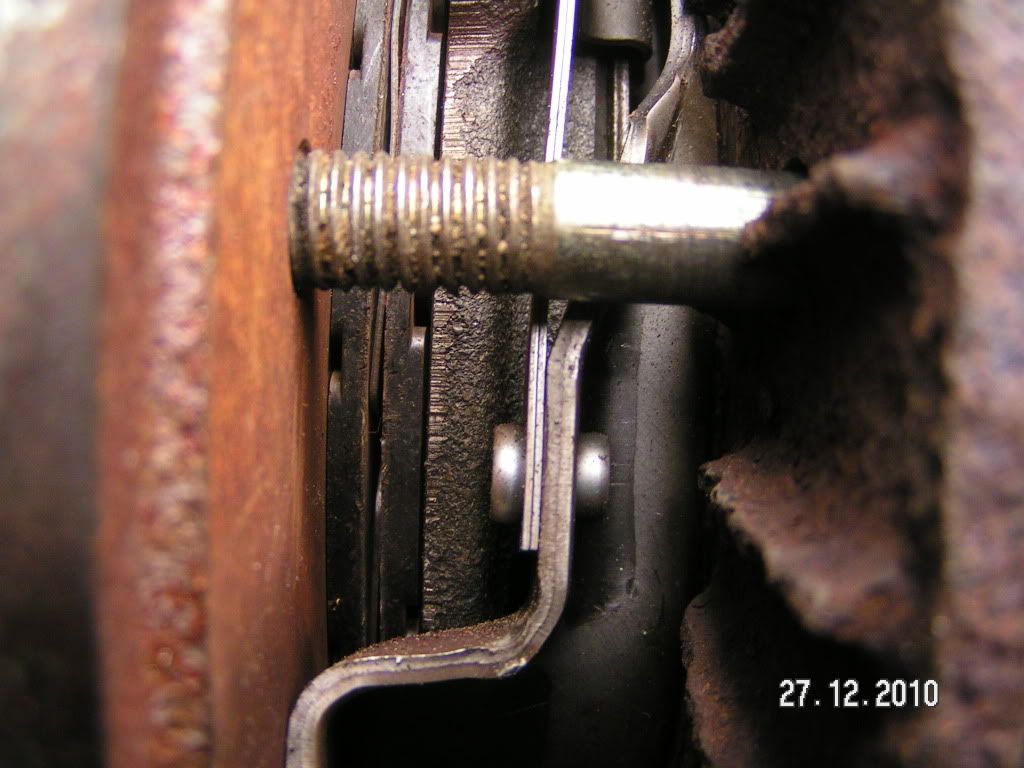

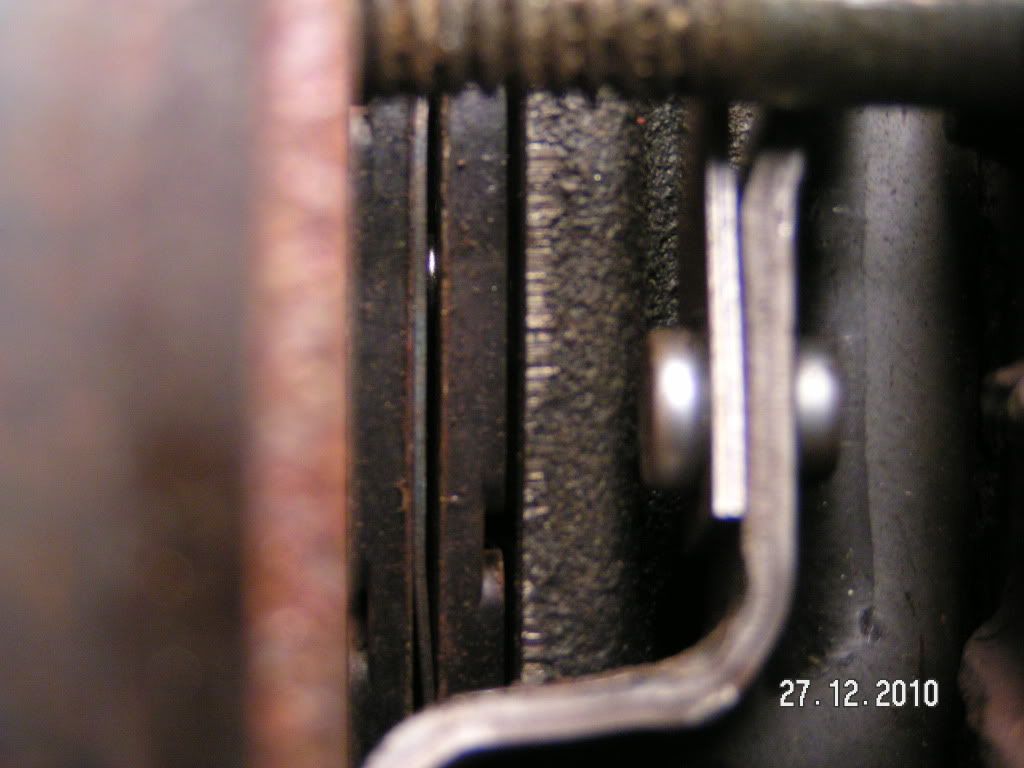

The clutch disk won't move easily with the clutch pedal down, even adjusted to max out the forward distance of the throw-out bearing (eg, hit that hard stop I talked about). It WILL move, but there is definitely too much drag. I agree that I SHOULD be able to move it easily in these conditions. What I see happening between the disk and the plate is that I can see the plate move backward, however, the spring cushion between the wear surfaces in the clutch plate expands the disk thickness as much as the plate can move back. So I end up with a still touching pressure plate, disk, flywheel situation. With a new clutch plate and disk, the pressure plate will stand well off the clutch disk. This one did when I put it in; it doesn't any more.... I can't think of what would have changed in the length of time this clutch has been in surface other than that the release fingers of the clutch pressure plate have lost temper, or for some other reason, no longer lift the the pressure plate itself.

Relative to the 'does it stop'... as it is currently, in high range on normal ground, yes. in low range in any gear on a flat paved surface, not really; it slows down a bit in the higher gears (in the low range); the clutch is obviously dragging; the engine rpms can change without the ground speed changing as quickly. All this says to me it is dragging.

It won't shift without grinding at all currently. I CAN get it into gear (with grinding); before the last clutch job, the only way I could shift without a scary amount of grinding was to shut the engine down.

I realize this isn't a synchromesh transmission with all the behaviors that go along with that.

Thanks again everyone!

Terry

The clutch disk won't move easily with the clutch pedal down, even adjusted to max out the forward distance of the throw-out bearing (eg, hit that hard stop I talked about). It WILL move, but there is definitely too much drag. I agree that I SHOULD be able to move it easily in these conditions. What I see happening between the disk and the plate is that I can see the plate move backward, however, the spring cushion between the wear surfaces in the clutch plate expands the disk thickness as much as the plate can move back. So I end up with a still touching pressure plate, disk, flywheel situation. With a new clutch plate and disk, the pressure plate will stand well off the clutch disk. This one did when I put it in; it doesn't any more.... I can't think of what would have changed in the length of time this clutch has been in surface other than that the release fingers of the clutch pressure plate have lost temper, or for some other reason, no longer lift the the pressure plate itself.

Relative to the 'does it stop'... as it is currently, in high range on normal ground, yes. in low range in any gear on a flat paved surface, not really; it slows down a bit in the higher gears (in the low range); the clutch is obviously dragging; the engine rpms can change without the ground speed changing as quickly. All this says to me it is dragging.

It won't shift without grinding at all currently. I CAN get it into gear (with grinding); before the last clutch job, the only way I could shift without a scary amount of grinding was to shut the engine down.

I realize this isn't a synchromesh transmission with all the behaviors that go along with that.

Thanks again everyone!

Terry