Hi- I'm new to the forum.

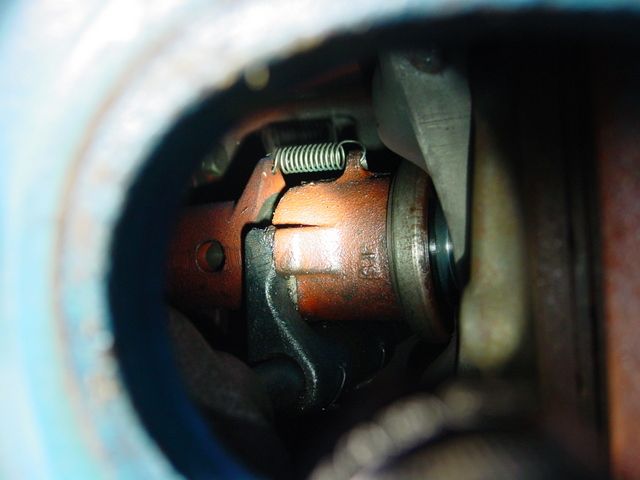

I bought a ford 1900 4x4 and the clutch is stuck. Does anyone know if this model as a site hole by the clutch assemble to look through. My tractor has a loader on it. And will need to take the loader frame off to see if it does. Also could I get a tool in there to move the throw out bearing if it is stuck? I want to try everything I can before I try to splt the tractor.

Any help is appreciated.

Thanks.

I bought a ford 1900 4x4 and the clutch is stuck. Does anyone know if this model as a site hole by the clutch assemble to look through. My tractor has a loader on it. And will need to take the loader frame off to see if it does. Also could I get a tool in there to move the throw out bearing if it is stuck? I want to try everything I can before I try to splt the tractor.

Any help is appreciated.

Thanks.