JC-jetro

Elite Member

I did try what BuzzardA19 recommended and tried turning the knob (that sets the speed at which the 3PH raises and lowers), this is not a true statement, the knob only helps with the rate of drop in and out several times to see if that made a difference. It did not. I still do not have any lift. I do still have my front hydraulics working on my loader though so the pump must be working. I don't have a pressure gauge to try what was suggested. In my shop manual it states:

The following are symptoms which may occur during operation of the hydraulic lift system and their possible causes. Use this information with TESTING and ADJUSTMENT information when diagnosing hydraulic lift problems.

Admittedly I do not know much about hydraulics so any advice would be appreciated. Has anyone had this model of tractor and had similar problems? All thoughts would be helpful. Thanks

I did also suggest to take the the nut off where the I put the gauge per pic on previous post. This will be somewhat messy if you have flow but takes nothing to do it. Need to have a helper to shut the engine off quickly. Don't try to block the flow with your finger as it will not work and will be dangerous. To avoid oil spill I try to put a temp elbow there and re-direct the flow using a hose in to a bucket.

Going back to the manual and their recommendation.

1. Hitch will not lift load. Could be caused by:

a. Restricted hydraulic oil filter.

If you had that your loader would not work either

b. Linkage out of adjustment or broken.

Possibility but doubt it as the are built pretty beefy. A quick look at the linkages to see if they have come apart might not be a bad idea

c. System relief valve pressure setting too low.

slight possibility, can not see it change all of the sudden unless you have some derbies blocking the port or broken spring. It is unlikely as you have hyd pump and loader working.

d. Safety relief valve faulty.

On their own, they very seldom fail due to robust design. Not too difficult to check.

e. "O" ring failure between control valve and valve cover.

very slight possibility in my opinion

f. Oil leakage past lift cylinder piston seal.

I give this the highest possibility and the best "bad outcome", that 's why I suggested you check pressure or flow. Once you know that it will help quite a bit. A question here, can you lift the arm without any load on 3 point?, if so , then raise the 3 point all the way and then turn the rate of drop knob clockwise to completely closed position and watch the arm on how quickly it comes down. That'll be your proof positive that is the seal.

g. Oil leakage pas lowering valve poppet.

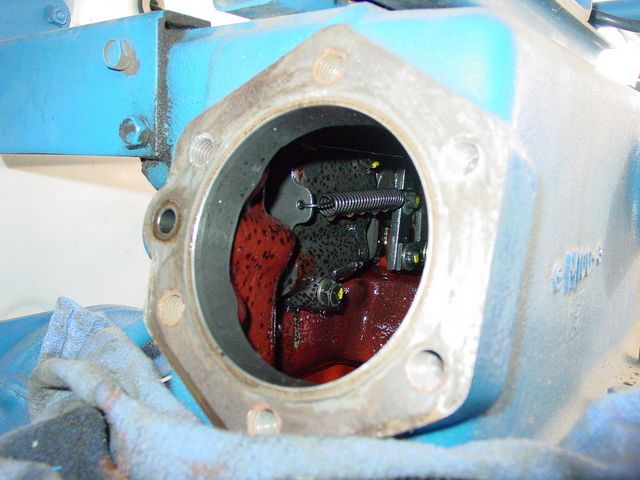

This would be the last thing I will ever dork with, you need to take seat off, and diffy cover just to see the spool valve. The spools and poppet are high quality machined part that by inspection only you'll find nothing. It take a lot of experience and 9.9 out of 10 they work flawlessly for the life of the tractor.

Check the flow thing and report back. By the way a gauge from is easily enough available for not much money. certainly excellent tool to have in the tool box.

JC,

Valley Instrument Hydraulic Pressure Gauge Liquid Filled, 5000 PSI | Filled Gauges| Northern Tool + Equipment