felixedo

Bronze Member

- Joined

- Jul 15, 2011

- Messages

- 50

- Location

- Missouri Ozarks

- Tractor

- New Holland TC35D / Deere 1026R / Bobcat CT2040

Greetings-

I have a TC35D with HST and about 215 hours (insert cracks about driving in parades, etc here ).

).

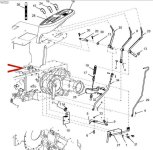

I can't engage the PTO. It was a little stiff in and out the last time I used it, just a couple of days ago, but now the lever won't budge. The linkage to the gear box appears to be free, but I haven't done any detail debugging, yet. I looked for a possible grease zerk that I may have been missing, but couldn't find anything.

Does anyone have experience with problems in this part of the machine? For what it's worth, I have the same problem with the 4WD, but since I don't ever really need to take it out of 4WD, I never bothered much with it. Both linkages are on the same side of the machine.

Thanks in advance .

I have a TC35D with HST and about 215 hours (insert cracks about driving in parades, etc here

I can't engage the PTO. It was a little stiff in and out the last time I used it, just a couple of days ago, but now the lever won't budge. The linkage to the gear box appears to be free, but I haven't done any detail debugging, yet. I looked for a possible grease zerk that I may have been missing, but couldn't find anything.

Does anyone have experience with problems in this part of the machine? For what it's worth, I have the same problem with the 4WD, but since I don't ever really need to take it out of 4WD, I never bothered much with it. Both linkages are on the same side of the machine.

Thanks in advance .