DieselPower

Elite Member

- Joined

- Sep 30, 2006

- Messages

- 2,756

- Location

- Fairfield, PA

- Tractor

- JD 3020, JD 4230, JD 7410, JD 2440, MF 750, NH LS170

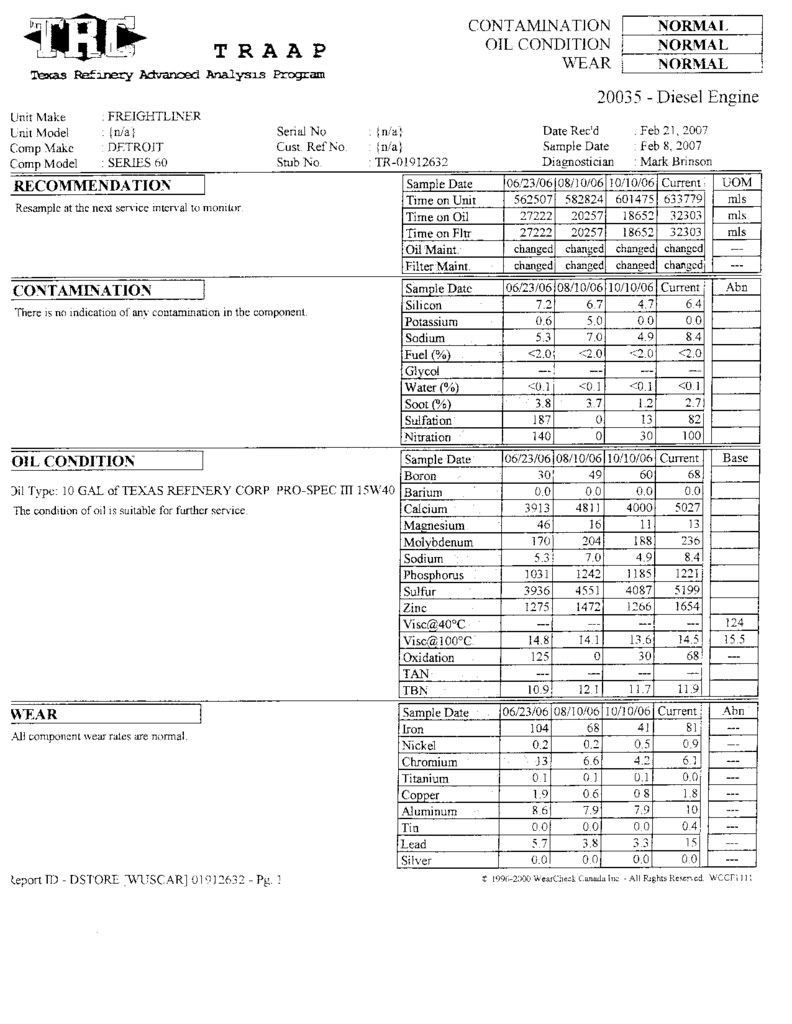

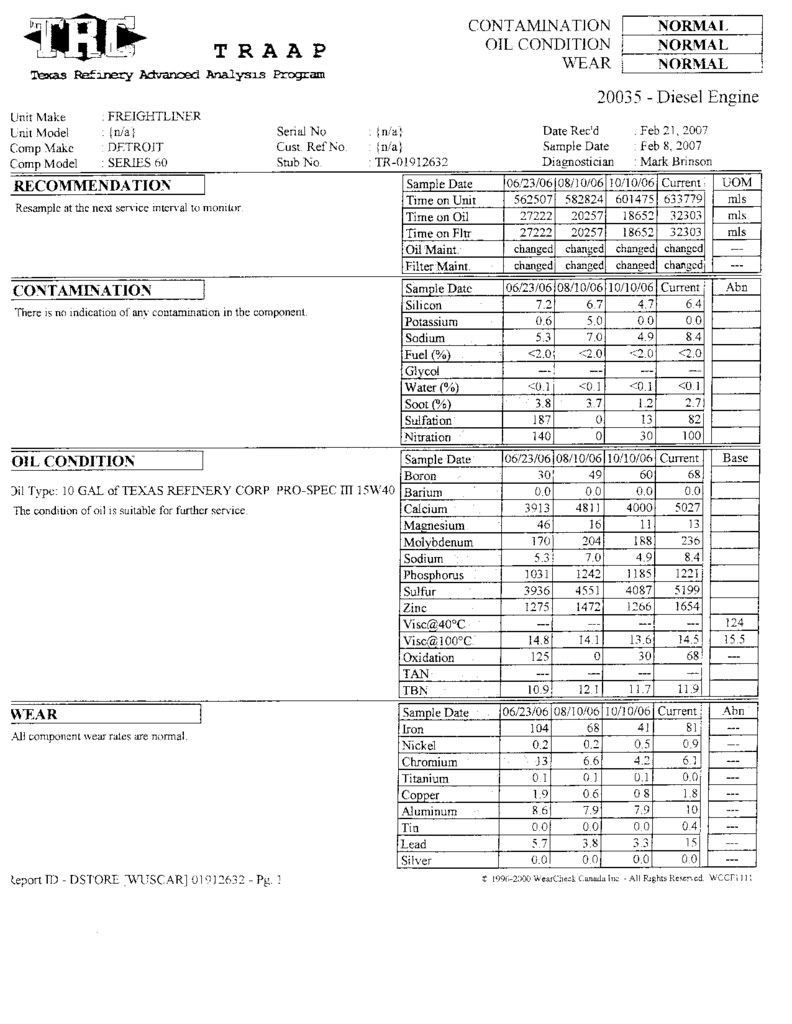

The topic seems to come up every week or so as to what a UOA (used oil analysis) is exactly. I thought I would post one so everyone can actually see what one looks like.

What is a UOA and how do you use it you ask. A UOA is performed for two main reasons. One (the most important one) is to check the oil for contamination and wear metals. Increased levels of soot, fuel, water and wear metals, etc... is a indicator that there is something wrong in the engine. Silicon levels on the rise, it's a good indicator that you either have a hole in your air filter or air intake system which is allowing dirt in. Potassium, Sodium and water levels on the rise, you probably have a leaking cylinder liner, liner o-ring or head gasket that is allowing antifreeze into the oil. High levels of Chromium and Titanium and Iron, it's a good indicator that you have increased cylinder liner/piston ring wear. Tin, Lead and Silver on the rise, your bearing's are wearing. These are just a few examples of what you can tell from a UOA.

Second reason for running a UOA program is to extend drain intervals. Just because you are using a high quality oil does not necessarily mean you can extend your drain intervals. Don't just come up with some arbitrary drain interval because you "think" the oil can last that long. With a UOA you can prove how long a lubricant can last. If you change your oil and the additive package is not depleted, the base oil is not worn out and you have no contamination or wear metals showing there is no reason to change the oil. If you do you are more or less dumping money down the drain. With a UOA you can "safely" extend your drain intervals. Let the oil itself tell you when it needs to be changed. Every vehicle, tractor and piece of equipment is different so why would they all have the same drain interval. One person may use their equipment harder than the next. One person may use better lubricants than the next and so on. Not only that but when the manufacturers set drain intervals and put them in a book they have to assume that the person is using the lowest quality oil that just meets their spec but will still attain a good service life. The point being that the published drain intervals are only suggestions since no two machines are the same or are used the same.

So, how do you administer a UOA program. In the beginning the first UOA should be taken at whatever your scheduled book drain interval is (not change the oil, just take the sample). When you get the analysis back see if the oil condition is still OK. If it is extend your interval out about 30%. Example: if the book calls for a 10,000 mile change interval do the first sample at 10,000, next one at 13,000, next one at 16,000 and so on. Keep adding 30% to the sampling frequency until the UOA comes back showing that the oil needs to be changed. Now back off 30%. This gives you a safety margin. So let's say you finally get out to 31,000 miles and the UOA report tells you to change the oil. You would want to set your new scheduled drain interval at no longer than 28,000 miles. From then on you would want to draw a sample at about 14,000 miles or half your new extended drain interval and again at 28,000 miles. The one at 14,000 miles is mainly to check for wear metals and contamination. Walla, you now have a safely run extended drain program set up. Let the lab tell you when to change your oil in your specific equipment and not a book that is just a general guideline.

The next question probably is, who can I get to do a UOA. There are numerous companies that do them. Some oil/lubricants manufacturers supply them at no charge for customers that use their product. You can also pay to have them done and the average is usually around $20.00. WearCheck, Blackstone Laboratories, Dyson Analysis (not cheap but the best and Terry personally reads every report) are just a few. Do a quick internet search and you will find numerous labs to pick from.

What is a UOA and how do you use it you ask. A UOA is performed for two main reasons. One (the most important one) is to check the oil for contamination and wear metals. Increased levels of soot, fuel, water and wear metals, etc... is a indicator that there is something wrong in the engine. Silicon levels on the rise, it's a good indicator that you either have a hole in your air filter or air intake system which is allowing dirt in. Potassium, Sodium and water levels on the rise, you probably have a leaking cylinder liner, liner o-ring or head gasket that is allowing antifreeze into the oil. High levels of Chromium and Titanium and Iron, it's a good indicator that you have increased cylinder liner/piston ring wear. Tin, Lead and Silver on the rise, your bearing's are wearing. These are just a few examples of what you can tell from a UOA.

Second reason for running a UOA program is to extend drain intervals. Just because you are using a high quality oil does not necessarily mean you can extend your drain intervals. Don't just come up with some arbitrary drain interval because you "think" the oil can last that long. With a UOA you can prove how long a lubricant can last. If you change your oil and the additive package is not depleted, the base oil is not worn out and you have no contamination or wear metals showing there is no reason to change the oil. If you do you are more or less dumping money down the drain. With a UOA you can "safely" extend your drain intervals. Let the oil itself tell you when it needs to be changed. Every vehicle, tractor and piece of equipment is different so why would they all have the same drain interval. One person may use their equipment harder than the next. One person may use better lubricants than the next and so on. Not only that but when the manufacturers set drain intervals and put them in a book they have to assume that the person is using the lowest quality oil that just meets their spec but will still attain a good service life. The point being that the published drain intervals are only suggestions since no two machines are the same or are used the same.

So, how do you administer a UOA program. In the beginning the first UOA should be taken at whatever your scheduled book drain interval is (not change the oil, just take the sample). When you get the analysis back see if the oil condition is still OK. If it is extend your interval out about 30%. Example: if the book calls for a 10,000 mile change interval do the first sample at 10,000, next one at 13,000, next one at 16,000 and so on. Keep adding 30% to the sampling frequency until the UOA comes back showing that the oil needs to be changed. Now back off 30%. This gives you a safety margin. So let's say you finally get out to 31,000 miles and the UOA report tells you to change the oil. You would want to set your new scheduled drain interval at no longer than 28,000 miles. From then on you would want to draw a sample at about 14,000 miles or half your new extended drain interval and again at 28,000 miles. The one at 14,000 miles is mainly to check for wear metals and contamination. Walla, you now have a safely run extended drain program set up. Let the lab tell you when to change your oil in your specific equipment and not a book that is just a general guideline.

The next question probably is, who can I get to do a UOA. There are numerous companies that do them. Some oil/lubricants manufacturers supply them at no charge for customers that use their product. You can also pay to have them done and the average is usually around $20.00. WearCheck, Blackstone Laboratories, Dyson Analysis (not cheap but the best and Terry personally reads every report) are just a few. Do a quick internet search and you will find numerous labs to pick from.