Mosey

Veteran Member

- Joined

- Jan 4, 2002

- Messages

- 1,571

- Location

- Conifer, Colorado

- Tractor

- 2000 New Holland TC29D with 7308 FEL, and top & tilt. 1950 John Deere B. 1940 Farmall A.

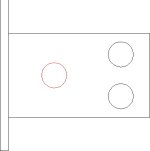

I'm planning to buy a hydraulic toplink. I haven't figured out the exact size I need yet. I was looking at the bracket on the back of my TC29D where the toplink attaches to the tractor. The bracket is about 4 1/2" long. It has 2 holes near the end of it. I've always used the top one. I'm considering drilling a new hole about 2" back from the other 2, but right in the center. See attachment (side view), the new hole is in red. That way, I could get a longer toplink and just attach it in the new hole for applications that needed a shorter one. Is it as simple as I think, or am I missing something? Will this weaken the bracket too much?