OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,824

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

100th diagram...

ouchers... i am completely out of ideas... of how to deal with the implements... on this new setup.

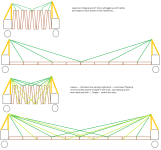

is there 2 hyd cylinders on each side. and they play hot potatoes. and pass implement back and forth between them when implement is up above the STB, to move implement from one side to other side...

discs would be fairly easy, just a hyd cylinder or 2, and you can quickly adjust angles of all the gangs of discs.

but for chisel plows, rippers... were they are J shape. planters that have boxes... and some sort of spring that pushes down into the ground... reset springs for plows / rippers...

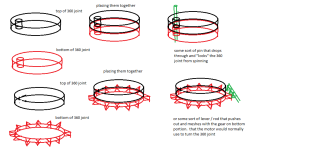

there is normally a single pipe that goes entire width of the implement. and chisles / rippers / discs get hung off of. perhaps instead of using box shape pipe. going with pipe O in shape. so these rows can be rolled over per row 180 degrees.

to state it, some sort of "crane" that does the moving of each implement from side to side and also turns implement 180 degrees...

does the STB act like a earth worm. getting shorter in length in field mode. and then longer in transport mode. and this switch from short to long. involves implements rotating from side to side...

is there 3 sets of hyd cylinders. 1 set on each side, to raise / lower, and adjust implement when it is down in the soil and then the 3rd set to flip the implement over to the other side...

i guess i am off to google regular old trains. and see if some pictures / video's give me some ideas... due to at this moment completely stuck in my tracks :/

ouchers... i am completely out of ideas... of how to deal with the implements... on this new setup.

is there 2 hyd cylinders on each side. and they play hot potatoes. and pass implement back and forth between them when implement is up above the STB, to move implement from one side to other side...

discs would be fairly easy, just a hyd cylinder or 2, and you can quickly adjust angles of all the gangs of discs.

but for chisel plows, rippers... were they are J shape. planters that have boxes... and some sort of spring that pushes down into the ground... reset springs for plows / rippers...

there is normally a single pipe that goes entire width of the implement. and chisles / rippers / discs get hung off of. perhaps instead of using box shape pipe. going with pipe O in shape. so these rows can be rolled over per row 180 degrees.

to state it, some sort of "crane" that does the moving of each implement from side to side and also turns implement 180 degrees...

does the STB act like a earth worm. getting shorter in length in field mode. and then longer in transport mode. and this switch from short to long. involves implements rotating from side to side...

is there 3 sets of hyd cylinders. 1 set on each side, to raise / lower, and adjust implement when it is down in the soil and then the 3rd set to flip the implement over to the other side...

i guess i am off to google regular old trains. and see if some pictures / video's give me some ideas... due to at this moment completely stuck in my tracks :/