OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,824

- Location

- Trivoli, IL

- Tractor

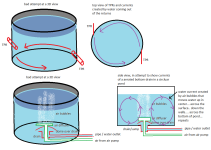

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

side tracking for a moment....

magnetic gearing vs gears or hydrualic fluid

Magnetic Couplings & Gearing - MGT HDV.mpg - YouTube

another magnetic gearing from different manufacture.

MAGNOMATICS' MAGNETIC GEAR AND PDD® MOTOR/GENERATOR - YouTube

it makes sense, just how well efficiency actually is.... and how much weight / amount of magnets to bring up that efficiency.

not sure what video above goes with below website, website gives a good amount of extra live rear world examples of what they have tried.

MGT - Magnetic Gearing & Turbine Corp: World Leader in Magnetic Gearing Technology

presentation slide show type of pdf file.

http://www.terramagnetica.com/papers/hatch-permanent-magnet-gears.pdf

===============

===============

getting back on track...

FairDiesel Limited received email back. that there current engine setup, should be possible to fit with what i want. but, there not in production point of yet. so what do i do? it would be nice to approach the bigger tractor manufactures and say hey, i need help, this is what i need. and yada yada yada.... but not sure how to approach and deal with problem at hand. at moment it is kinda like what comes first (chicken or the egg). for engine folks, due they just build something, and then let everyone build around the engine, or due build the item what ever it maybe, and find an engine that meets requirements. or rather hopefully get a complete mix of working back and forth.

Engine Technology, Vehicle, Marine, Light Aircraft, Multi Fuel

to many posts to look back when i emailed them. to find out specs. and they noted they were getting things ready in production or something...and really did not get any sort of information. and then checking out there website yesterday, they have updated there website with dimensions, graphs, and then i see below statement on there website....

not sure what this is about, there was mention of turning one into an engine.

Cylindrical Energy Module (from Internet Glossary of Pumps)

possible alternative to dukeengines or fairdiesel, and first mention that i can remember of agriculture in application notations.

S-RAM Dynamics

================

================

steam engine, but a wide amount of videos showing a rotatory style engine.

Green Steam Engine Home Page

================

found a "web ring" for mazda rotatory engines. giving links to various companies.

Mazda Rotary

on one of the sites of the web ring, came across, Craig's Rotary Page: John Deere Rotary Engines "John Deere" building a wankle / rotatory engine. back in the 1990's it is not much, but something.

that data of webring, and websites i saw, go back to 2004 to 2007. and did not see much of an update across websites. guessing someone went around trying to find businesses or like and created the webring.

http://www.rotarytop150.com/ another source... for companies / folks dealing with wankle / rotary engines.

mazdarotaryclub.com forum seems to have a good amount of posts.

Aircraft Rotary Engine News Letter good amount of pictures and graphs, and various engines. granted no physical dimensions, but pictures help protray a engine type that should fit the SSTT (sideways snake train tractor)

finally found dimensions and descent explanation of them dimensions of a rotatory engine.

How much does an RX8 Engine Weigh? - RX8Club.com

21 inches long x 17 inches high 12 inches wide.

================

================

areas of other forums, (when going back to there older threads) covering a wider amount of engine types and what ever may be the latest greatest thing out there.

Firewall Forward / Props / Fuel system

Propulsion - Boat Design Forums

===============

===============

with limitations of what is currently out there (engines producing X amount of HP), and there length, width, height dimensions. it is looking more like i maybe. going with more of a "multi engine" setup. every 15 footer section. would have its own engine, generator, hyd pump, fuel tank, radiators, etc.... vs staying with a single larger engine that drives 3 to 4 sections.

it has its con's and the pro's... from 3 to 4 engines vs 1 bigger engine...

more engines

--more things that could go wrong and most likely fail.

--backup, if one engine goes down, another engine to pickup its area,

--ability to have say 15 to 20 foot section that has its own power on smaller fields. and then being able to hook a few of them up for larger fields.

--always seems a single larger engine is more fuel efficient than a bunch of smaller engines. when speaking pure amount of fuel consumed vs HP created.

--i suppose a farmer could mix and match to some degree between "powered sections" vs non powered sections. and mix and match for implement that will be in the field.

--multiple engines setup, would allow one smaller engine to run full on right at its BEP (best efficient point), and then as needed turn on another engine, to gain what ever extra HP was needed for task at hand.

--multiple smaller engines, would not require a "engine swap" from 600HP engine to say 150HP engine. you would simple mix and match "powered sections" with non powered sections.

--might provoke a "mass production" and in that saving more on cost of parts and like. due to multi engines, etc... being duplicated over and over again on each section.

--major con, most likely is additional weight.

--major con, maintenance nightmare, each section would need to be serviced individually. PLUS SIDE, if one engine / section goes down for what ever reason, and if there are enough powered engines connected for what ever ya doing in field. you could keep on going. if you were preping a week or a couple days before hand trying to get ready for fields to be just right. and find a problem, you could pull that section out, and still have other sections to at least get ya going in the field, until repair tech gets out there or part arrives or the like.

--non power section, might have extra fuel tank/s, or perhaps gutted out, to allow for some sort of "grain wagon" were grain comes out of middle bottom of the frame. pulling grain around does not require a whole lot of HP, compared to say a tiller (tines) / rotatory cultivator. or a bottom plow.

major issue, i would need to create a better "quick connect" per say between sections. vs relying on bolts/nuts or even welding stuff directly into place. so a single person could control multi sections as one large setup. and/or each section was independent of each other, and operated more like controlled traffic in the field. were drone tractor follows a lead tractor.

i am still gun ho, of trying to maximize 60 feet. to deal with road laws. and dealing with the SSTT needing to flex within the field to deal with slopes/hills. and dealing with wet spots, and wanting multi sections connected together to possibly keep more wheels on dryer dirt to pull/push the SSTT through. along with multi sections connected together to get down the road.

===============

recap....

engine threads i have created

trying to find a engine that will fit some dimensions - Hot Rod Forum : Hotrodders Bulletin Board

trying to find an engine to fit some dimensions.

looking for an eninge that will fit some dimensions - Boat Design Forums

magnetic gearing vs gears or hydrualic fluid

Magnetic Couplings & Gearing - MGT HDV.mpg - YouTube

another magnetic gearing from different manufacture.

MAGNOMATICS' MAGNETIC GEAR AND PDD® MOTOR/GENERATOR - YouTube

it makes sense, just how well efficiency actually is.... and how much weight / amount of magnets to bring up that efficiency.

not sure what video above goes with below website, website gives a good amount of extra live rear world examples of what they have tried.

MGT - Magnetic Gearing & Turbine Corp: World Leader in Magnetic Gearing Technology

presentation slide show type of pdf file.

http://www.terramagnetica.com/papers/hatch-permanent-magnet-gears.pdf

===============

===============

getting back on track...

FairDiesel Limited received email back. that there current engine setup, should be possible to fit with what i want. but, there not in production point of yet. so what do i do? it would be nice to approach the bigger tractor manufactures and say hey, i need help, this is what i need. and yada yada yada.... but not sure how to approach and deal with problem at hand. at moment it is kinda like what comes first (chicken or the egg). for engine folks, due they just build something, and then let everyone build around the engine, or due build the item what ever it maybe, and find an engine that meets requirements. or rather hopefully get a complete mix of working back and forth.

Engine Technology, Vehicle, Marine, Light Aircraft, Multi Fuel

to many posts to look back when i emailed them. to find out specs. and they noted they were getting things ready in production or something...and really did not get any sort of information. and then checking out there website yesterday, they have updated there website with dimensions, graphs, and then i see below statement on there website....

will wait before emailing them again. till i take some more time trying to search down other engines out there already.Duke Engines is looking for international co development and licensing partners for its range of unique axial engines.

not sure what this is about, there was mention of turning one into an engine.

Cylindrical Energy Module (from Internet Glossary of Pumps)

possible alternative to dukeengines or fairdiesel, and first mention that i can remember of agriculture in application notations.

S-RAM Dynamics

================

================

steam engine, but a wide amount of videos showing a rotatory style engine.

Green Steam Engine Home Page

================

found a "web ring" for mazda rotatory engines. giving links to various companies.

Mazda Rotary

on one of the sites of the web ring, came across, Craig's Rotary Page: John Deere Rotary Engines "John Deere" building a wankle / rotatory engine. back in the 1990's it is not much, but something.

that data of webring, and websites i saw, go back to 2004 to 2007. and did not see much of an update across websites. guessing someone went around trying to find businesses or like and created the webring.

http://www.rotarytop150.com/ another source... for companies / folks dealing with wankle / rotary engines.

mazdarotaryclub.com forum seems to have a good amount of posts.

Aircraft Rotary Engine News Letter good amount of pictures and graphs, and various engines. granted no physical dimensions, but pictures help protray a engine type that should fit the SSTT (sideways snake train tractor)

finally found dimensions and descent explanation of them dimensions of a rotatory engine.

How much does an RX8 Engine Weigh? - RX8Club.com

21 inches long x 17 inches high 12 inches wide.

================

================

areas of other forums, (when going back to there older threads) covering a wider amount of engine types and what ever may be the latest greatest thing out there.

Firewall Forward / Props / Fuel system

Propulsion - Boat Design Forums

===============

===============

with limitations of what is currently out there (engines producing X amount of HP), and there length, width, height dimensions. it is looking more like i maybe. going with more of a "multi engine" setup. every 15 footer section. would have its own engine, generator, hyd pump, fuel tank, radiators, etc.... vs staying with a single larger engine that drives 3 to 4 sections.

it has its con's and the pro's... from 3 to 4 engines vs 1 bigger engine...

more engines

--more things that could go wrong and most likely fail.

--backup, if one engine goes down, another engine to pickup its area,

--ability to have say 15 to 20 foot section that has its own power on smaller fields. and then being able to hook a few of them up for larger fields.

--always seems a single larger engine is more fuel efficient than a bunch of smaller engines. when speaking pure amount of fuel consumed vs HP created.

--i suppose a farmer could mix and match to some degree between "powered sections" vs non powered sections. and mix and match for implement that will be in the field.

--multiple engines setup, would allow one smaller engine to run full on right at its BEP (best efficient point), and then as needed turn on another engine, to gain what ever extra HP was needed for task at hand.

--multiple smaller engines, would not require a "engine swap" from 600HP engine to say 150HP engine. you would simple mix and match "powered sections" with non powered sections.

--might provoke a "mass production" and in that saving more on cost of parts and like. due to multi engines, etc... being duplicated over and over again on each section.

--major con, most likely is additional weight.

--major con, maintenance nightmare, each section would need to be serviced individually. PLUS SIDE, if one engine / section goes down for what ever reason, and if there are enough powered engines connected for what ever ya doing in field. you could keep on going. if you were preping a week or a couple days before hand trying to get ready for fields to be just right. and find a problem, you could pull that section out, and still have other sections to at least get ya going in the field, until repair tech gets out there or part arrives or the like.

--non power section, might have extra fuel tank/s, or perhaps gutted out, to allow for some sort of "grain wagon" were grain comes out of middle bottom of the frame. pulling grain around does not require a whole lot of HP, compared to say a tiller (tines) / rotatory cultivator. or a bottom plow.

major issue, i would need to create a better "quick connect" per say between sections. vs relying on bolts/nuts or even welding stuff directly into place. so a single person could control multi sections as one large setup. and/or each section was independent of each other, and operated more like controlled traffic in the field. were drone tractor follows a lead tractor.

i am still gun ho, of trying to maximize 60 feet. to deal with road laws. and dealing with the SSTT needing to flex within the field to deal with slopes/hills. and dealing with wet spots, and wanting multi sections connected together to possibly keep more wheels on dryer dirt to pull/push the SSTT through. along with multi sections connected together to get down the road.

===============

recap....

engine threads i have created

trying to find a engine that will fit some dimensions - Hot Rod Forum : Hotrodders Bulletin Board

trying to find an engine to fit some dimensions.

looking for an eninge that will fit some dimensions - Boat Design Forums