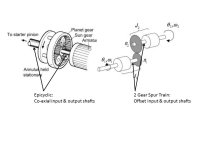

I had failed planetary parts on display all over my office and at home until I retired and my wife made me get rid of most. Planetaries are nice, can provide higher gear reductions in more compact designs, but have lots of parts. There are the gears, but gears rotate on bearings, and the bearings are between the gears and supporting shafts, all which must be machined and heat treated, then ground to near perfection. The gear train is only as good as the weakest link. If the design capability is identical, the simpler design will be more reliable but usually there are additional parameters involved like space constraints. I know companies will promote their planetary design - I know, I helped write the BS because it sounds good. What really counts is whether or not it will do the job. What I often worked with required 60:1 to 110:1 reduction ratios and to get a compact design that will handle the torque dictates planetary drives. More important is the manufacturer's reputation.