Making post holes in my soil is a combination of trying to start the hole with the auger and when it stops digging after a couple inches, get out the digging bars and manual rock post hole digger. Then back on the tractor with the auger for a few more inches- or none at all or dig a foot if one is lucky. To be even luckier is to have someone available who can run the tractor while I am directing, digging and trying to fracture rocks with the digging bar. One of the most recent 9" holes took four hours to dig with me on my knees with the digging bar and the wife on the tractor moving the auger in and out of the "hole" so I could dig.

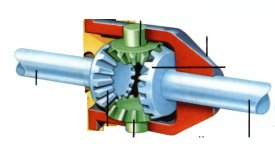

On the next to the last hole (have been digging holes for 6 weeks or so), the auger was all of the way down and apparently hooked a rock with the flight and sheared the shear bolt. After a couple more shear bolts it was obvious it was not going anywhere the easy way. And because the auger was all of the way down with all three safety shields in place, it was nearly impossible to get access to its two mounting bolts to disconnect the auger from the gear box. It took the first couple hours just to get one of the shields removed and the auger disconnected from the PHD gear box.

Tried various things and the next day purchased a 48" pipe wrench which would not budge it. So in the end a chain on the end of the wrench attached to the tractor's draw bar did the trick- 1/4 turn at a time for a couple complete turns and then was able to lift it out with the FEL. One more "primary" hole left to go and it will be the worst one yet. Then will try and drive some T-posts and see how many will not require the PHD and concrete...

BTW: I have the ETA 6900HD PHD and it uses the Speeco HD augers. Previously using a TSC (SpeeCo) HD PHD with the TSC (SpeeCo) regular duty augers (go figure). I mangled a 9" auger and damaged a 12" auger. So far the Speeco HD augers are true to their name and no damage to this one yet.

On the next to the last hole (have been digging holes for 6 weeks or so), the auger was all of the way down and apparently hooked a rock with the flight and sheared the shear bolt. After a couple more shear bolts it was obvious it was not going anywhere the easy way. And because the auger was all of the way down with all three safety shields in place, it was nearly impossible to get access to its two mounting bolts to disconnect the auger from the gear box. It took the first couple hours just to get one of the shields removed and the auger disconnected from the PHD gear box.

Tried various things and the next day purchased a 48" pipe wrench which would not budge it. So in the end a chain on the end of the wrench attached to the tractor's draw bar did the trick- 1/4 turn at a time for a couple complete turns and then was able to lift it out with the FEL. One more "primary" hole left to go and it will be the worst one yet. Then will try and drive some T-posts and see how many will not require the PHD and concrete...

BTW: I have the ETA 6900HD PHD and it uses the Speeco HD augers. Previously using a TSC (SpeeCo) HD PHD with the TSC (SpeeCo) regular duty augers (go figure). I mangled a 9" auger and damaged a 12" auger. So far the Speeco HD augers are true to their name and no damage to this one yet.