Well here's today's work. Slowly getting there.

Taking apart the galled up piston. Used snap ring pliers to get the pin started out, then a pick to work it the rest of the way. The pins were tight in the cylinders, although not bad in the rod. When I re-assembled, I stuck the wrist pin in the freezer and the piston in the oven at 300. When I put them back together, the pin just dropped in. Eliminated having to use an arbor press.

Here's a shot of the components of the piston laid out.

Also checked the side gap of the rings. If they bounce around in there long enough, it will make the gap between the ring and land too large, requiring replacement of the piston. The used ones here were at .002, which again, is fine.

Using a bore gage to check the cylinder. I normally check it at 90 degrees in 2-3 different locations, top to bottom. Here, everything was not more then a couple tenths taper and nice and round. All three nearly identical. The two old pistons went in with .002 piston to cylinder wall clearance; the new piston was .0015. New piston was coated, old ones were not.

Checking the ring gap. Here I had just about .010, which was fine.

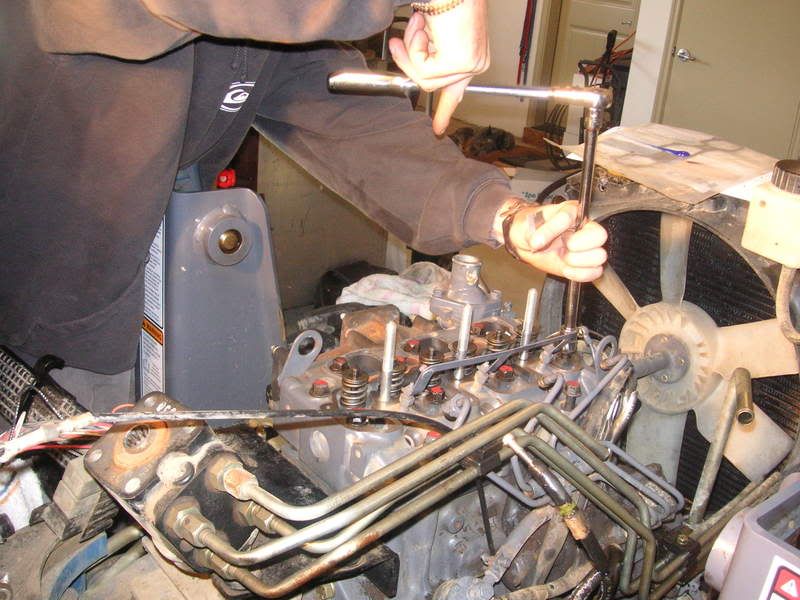

Bolting and torquing the head down. It called for about 80 ft/lb of torque, so we did it in increments of 10, 25, 75 and 80. Then let it sit for a bit and re-checked. Cast iron parts don't move as much as aluminum, but its always a good idea to re-check torque.

Time to set the valves. They set almost like and old VW; .008 clearance.

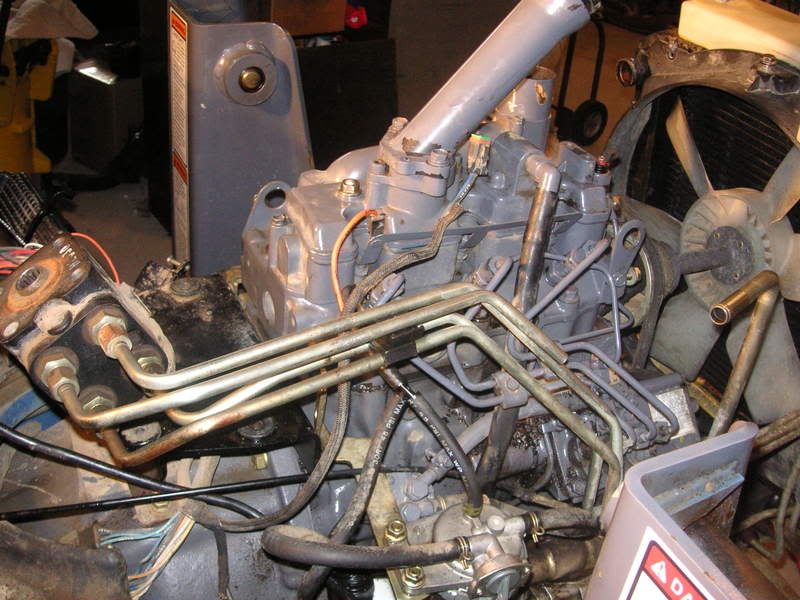

Engine back together.

Cowling, steering wheel and side covers starting back on.

That about did it for today. Had a couple glitches. Broke one air intake bolt off. Had to drill it and use an EZ out to remove. Its an odd one so will have to pick one up at Fastenal tomorrow. Also pulled a real boner when I bolted the rocker box down. I ended up putting the nuts on after I stuck the valve cover on..don't ask. Had to pull that back apart and re check everything.

Should finish up with the assembly tomorrow.