tommu56 has given you the correct advice. I am no expert because I usually give up and cut the bearing off with an oxy-acetylene torch.

That appears to be about a 1" shaft. In my experience the rust between the shaft and bearing quickly freezes the parts together very tightly for three reasons: one, there is very little clearance, so not much rust is needed to jam the parts; two, neither surface is painted (the black oxide or black phosphate coat that might be on a quality bearing is not much protection); and three, on a mower the shaft frequently gets wet from rain or dew or even the moisture in the grass blades.

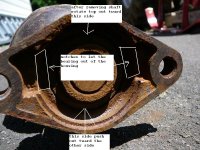

It appears that the roller has a sleeve welded onto the end and a short shaft has been inserted into the sleeve and fixed with a pin. The shaft then sticks out enough to pass through the bearing. If the bearing is pushed up close to the sleeve, you may have trouble getting a bearing separator between the sleeve and the inner race of the bearing. If you can't get the separator into that position, all the force will be against the bearing housing and, since it is cast iron, it will probably break. Even if it does not break, the side force on the bearing will probably shorten its life considerably, and it would be wise to replace it.

I have also found that there are only two classes of mounted ball bearings, like your two-bolt flange: Cheap (under $10.00) and Good ($30.00 -50.00). I replace several 1" pillow blocks each year. After paying McMaster Carr $35 apiece for four new ones a year ago, I decided this year to try the $7 ones from Surplus Center. Of the four new ones I ordered, one was almost too rough to turn when I got it (I think the balls may have been square), and two of the remaining three lasted less than one month.

So, I would try to pull the old bearing off with a separator like tommu56 said, if you can get one in place. If you can't get it into position, or if the bearing just will not move after one or more good soakings with PB Blaster, application of the separator, and several good licks on the end of the shaft with a brass punch, give up and cut the old one off. If you do not have access to an OA torch, an angle grinder (4 1/2" with a 1/16 or 1/8" cutoff blade) works pretty well. Cut through one side of flange and a few raps with a hammer should break it. Then do the same with the outer race. When you get to the inner race, be careful not to cut into the shaft (although a small nick is not likely to weaken it enough to matter). I usually make a groove parallel to the shaft that doesn't quite reach down to the shaft surface. Then strike a cold chisel into the groove. The bevel of the chisel will usually split the inner race the rest of the way.

Good luck.