You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Press advice appreciated

- Thread starter EddieWalker

- Start date

/ Drill Press advice appreciated

#11

RedDirt

Gold Member

- Joined

- Dec 4, 2007

- Messages

- 469

- Location

- Northern Idaho

- Tractor

- Kubota BX23, Wards 16HP HST Garden Tractor, (previous) D2 Logging Cat

Eddie,

Hold downs, not press itself...I've become addicted to the purpose built vise-grip type hold downs. I think Delta developed these but HF has knock-offs that work just as well and cost much less. Usually just one well-placed hold down will keep the work piece from spinning as the bit punches through the workpiece. To help avoid the tendency to grab at punch through ease the feed pressure as the bit is cutting through the bottom.

I came close to chewing up my holding hand a couple of time before using these clamps and never since I starting clamping. They are easy to attach, adjust and use especially if the table has slots. A good investment for your new drill press at $7.50-$12+/-.

Hold downs, not press itself...I've become addicted to the purpose built vise-grip type hold downs. I think Delta developed these but HF has knock-offs that work just as well and cost much less. Usually just one well-placed hold down will keep the work piece from spinning as the bit punches through the workpiece. To help avoid the tendency to grab at punch through ease the feed pressure as the bit is cutting through the bottom.

I came close to chewing up my holding hand a couple of time before using these clamps and never since I starting clamping. They are easy to attach, adjust and use especially if the table has slots. A good investment for your new drill press at $7.50-$12+/-.

srjones

Platinum Member

- Joined

- Mar 6, 2006

- Messages

- 542

- Location

- Columbia County, Oregon, USA

- Tractor

- Mahindra 2015HST & Mitsubish R1500

Hi Eddie,

I got a JET years ago...still running strong. Whatever you decide, I have 3 tips you might find useful when drilling many holes in steel.

1. Drill a pilot hole with a small bit (1/8"-1/4") first. You'll have less wander getting the hole started where you want it to be.

2. Use cutting oil. The stuff is messy but it sure does work.

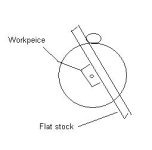

3. There certainly is a risk that the peice will catch as it poke through the metal and start spinning. Take a flat bar and hold the end with with your left hand while wedging the back end of the bar on the opposite side of the drill press post. (see attached diagram)

I got a JET years ago...still running strong. Whatever you decide, I have 3 tips you might find useful when drilling many holes in steel.

1. Drill a pilot hole with a small bit (1/8"-1/4") first. You'll have less wander getting the hole started where you want it to be.

2. Use cutting oil. The stuff is messy but it sure does work.

3. There certainly is a risk that the peice will catch as it poke through the metal and start spinning. Take a flat bar and hold the end with with your left hand while wedging the back end of the bar on the opposite side of the drill press post. (see attached diagram)

Attachments

mjncad

Super Member

Eddie:

I have the following Jet model that I'm pleased with. Jet has made some minor changes since I bought mine in the mid 90's. What sold me on the Jet over the Delta and Craftsman was the depth stop; it is a nice simple screw and two knurled lock nuts. Much easier to read and set than the goofy rotary ones on the quill handle shaft. WMH ® - JDP-17MF, 16-1/2 Floor Drill Press, 5/8 Capacity, 3/4HP, 16 Speed

I agree with RedDirt concerning these hold downs, they are indispensable and I have one of each size (6", 9" & 11"). I leave mine a little loose when I attach them to the table so I can move them out of the way quickly for the next setup. This has the effect of loosening the pressed on vise grip part of the clamp to the clamp bolt plate. Whenever I buy a new clamp, the first thing I do is weld the vise grip portion to the clamp bolt plate. If you need a picture showing this simple fix, let me know and I'll snap one for the forum.

Last tip...whatever you buy, floor or bench mounted...bolt it down! Drill presses are inherently top heavy, and I personally would never put one on a mobile stand like HTC and other companies market.

I have the following Jet model that I'm pleased with. Jet has made some minor changes since I bought mine in the mid 90's. What sold me on the Jet over the Delta and Craftsman was the depth stop; it is a nice simple screw and two knurled lock nuts. Much easier to read and set than the goofy rotary ones on the quill handle shaft. WMH ® - JDP-17MF, 16-1/2 Floor Drill Press, 5/8 Capacity, 3/4HP, 16 Speed

Eddie,

Hold downs, not press itself...I've become addicted to the purpose built vise-grip type hold downs. I think Delta developed these but HF has knock-offs that work just as well and cost much less. Usually just one well-placed hold down will keep the work piece from spinning as the bit punches through the workpiece. To help avoid the tendency to grab at punch through ease the feed pressure as the bit is cutting through the bottom.

I came close to chewing up my holding hand a couple of time before using these clamps and never since I starting clamping. They are easy to attach, adjust and use especially if the table has slots. A good investment for your new drill press at $7.50-$12+/-. RedDirt

I agree with RedDirt concerning these hold downs, they are indispensable and I have one of each size (6", 9" & 11"). I leave mine a little loose when I attach them to the table so I can move them out of the way quickly for the next setup. This has the effect of loosening the pressed on vise grip part of the clamp to the clamp bolt plate. Whenever I buy a new clamp, the first thing I do is weld the vise grip portion to the clamp bolt plate. If you need a picture showing this simple fix, let me know and I'll snap one for the forum.

Last tip...whatever you buy, floor or bench mounted...bolt it down! Drill presses are inherently top heavy, and I personally would never put one on a mobile stand like HTC and other companies market.

milkman

Elite Member

- Joined

- Sep 22, 2001

- Messages

- 3,629

- Tractor

- BX2200, BCS 735

I have a floor model similar to the HF one pictured, got it when Central Tractor went out of business a few years ago. I think the lowest speed is 250 and that's faster than I like, but when drilling steel, I use plenty of lube.

I put a rail around the deck and used round aluminum spindles between 2X rails and had to drill a bunch of holes in the edge of the 2X for the spindles to set in, dirll press has a depth stop and it came in real handy drilling all those holes to the same depth.

I put a rail around the deck and used round aluminum spindles between 2X rails and had to drill a bunch of holes in the edge of the 2X for the spindles to set in, dirll press has a depth stop and it came in real handy drilling all those holes to the same depth.

barneyrb

Silver Member

- Joined

- Mar 9, 2008

- Messages

- 183

Whatever you buy make sure that it has a totally enclosed motor. Electric motors that have openings (so you can see windings in the motor) have magnetizing forces inside and will attract small metal particles into all the wrong places.

If you've never used a drill press before you will love using one. Very precise compared to a hand drill. It is also not as necessary to drill a pilot hole as the whole unit is solid and not likely to wander when starting to drill. For drilling metal the use of cutting oil constantly being pumped onto the work is a real advantage as it lubricates and keeps heat from building up. Yes you can drill metal without it but the drill bits won't last as long and it is slower cutting. Any drill press is good when you compare it to a hand drill however you can get better quality if you really need it. In my opinion multiple speed is an essential. The complaint I have with mine is the chuck doesn't seem to grip the bits as well as I would like. I really have to tighten the chuck with the key inserted one at a time in the 3 key holes. The good news is most chucks can be replaced with better versions.

EddieWalker

Epic Contributor

Thank you everyone for your advice and recomendations. I've looked around online at the models and sites mentioned, but really want to take a look at them first hand.

It's funny, but I'm in a hardware/tool store of some kind several times a week and in my entire life, I've never looked at drill presses. Walked past them, but never stoped to check them out.

Just reading the posts this morning has been an education. I knew there would be some things to look for, but didn't realize there would be so much.

Eddie

It's funny, but I'm in a hardware/tool store of some kind several times a week and in my entire life, I've never looked at drill presses. Walked past them, but never stoped to check them out.

Just reading the posts this morning has been an education. I knew there would be some things to look for, but didn't realize there would be so much.

Eddie

Charlesaf3

Veteran Member

- Joined

- Aug 17, 2006

- Messages

- 1,984

- Location

- Richmond VA & Irvington VA

- Tractor

- Kubota B3030, Kubota M59 TLB

I've got the little one home depot sells. Fine for jobsite, but I'd steer clear. It doesn't have near enough power - a big spade bit in Mahogany really makes it struggle

bjr

Veteran Member

I got the 16 speed Harbor Freight model that the other poster showed and drill a lot of 3/4" and some 7/8 in 1/2 thick and some times 1" metal. I need new belts now and wish it turn slow like 50 rpms but I get the job done. bjr