I was doing a little faucet plumbing last night and came upon a question that applies to hydraulic fittings. The water lines for the faucet I was working on were more like hydraulic lines (braided flex to stainless) than conventional poly water lines (Hans Grohe, the Germans don’t fool around).

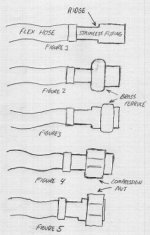

I have attached a crude drawing to help with my question.

Figure 1 shows the fitting. The solid stainless end has a ridge. It is greatly exaggerated in the drawing; in reality the difference in diameters is only a few microns I suppose.

Is the brass ferrule for the compression fitting supposed to sit slightly on the ridge when the compression is made as shown in figure 2 (compression nut missing from drawing) or is it supposed to sit beyond the ridge as shown in figure 3. In the first case, when the compression nut is on, after initial compression it will be held on by the ferrule, which cannot slide beyond the ridge (figure 4), in the latter case it would appear that the ridge would be an indicator letting you know how far the fitting is sitting in its mate so that the ferrule is properly positioned.

In the first case not only is the ferrule held on by the ridge, the fitting (and hose) can’t slide backward from the compression nut and out of the fitting. However, my concern is that the only point of seal is right on the ridge.

In the latter case, the ferrule has more surface area to form a better seal, but the fitting might be more likely (might) to slide back out of the compression nut.

1) I’m not sure which of the two ways is proper.

2) Once you do the initial compression in the first case how do you remove the ferrule if you have to, now that it doesn’t want to slide beyond the ridge without damaging the surface area of the stainless fitting?

Thanks,

-- Rock

I have attached a crude drawing to help with my question.

Figure 1 shows the fitting. The solid stainless end has a ridge. It is greatly exaggerated in the drawing; in reality the difference in diameters is only a few microns I suppose.

Is the brass ferrule for the compression fitting supposed to sit slightly on the ridge when the compression is made as shown in figure 2 (compression nut missing from drawing) or is it supposed to sit beyond the ridge as shown in figure 3. In the first case, when the compression nut is on, after initial compression it will be held on by the ferrule, which cannot slide beyond the ridge (figure 4), in the latter case it would appear that the ridge would be an indicator letting you know how far the fitting is sitting in its mate so that the ferrule is properly positioned.

In the first case not only is the ferrule held on by the ridge, the fitting (and hose) can’t slide backward from the compression nut and out of the fitting. However, my concern is that the only point of seal is right on the ridge.

In the latter case, the ferrule has more surface area to form a better seal, but the fitting might be more likely (might) to slide back out of the compression nut.

1) I’m not sure which of the two ways is proper.

2) Once you do the initial compression in the first case how do you remove the ferrule if you have to, now that it doesn’t want to slide beyond the ridge without damaging the surface area of the stainless fitting?

Thanks,

-- Rock