paroxysm3

New member

- Joined

- May 15, 2009

- Messages

- 15

This is for a JD 855 w/Yanmar 3TN75. I had the injection pump rebuilt, but in the battle to remove it (I broke one gear puller) I lost the alignment mark I'd painted on the gears. The Component Technical Manual (CTM3-10AUG93) has a procedure for setting the timing, but I have a few questions to understand if I've done this correctly.

Q1. Is the timing set at the beginning of the injection cycle or the end?

First is confusion over whether the timing mark is set by start of the injection or at the end. The CTM calls for a Timing tool "No 1 fuel injection line cut off at first bend." Later the manual asks to observe when the "tip of the timing tool becomes MOIST [sic] with solid fuel."

I'm not cutting off my fuel line, so I've been doing this by observing the smallest change in the number 1 injector. However, I've also read about doing the timing using the "Spill Cut Off Point" method which waits till the pump cycle is finished. Is this the purpose of the Timing Tool? That is, is the fuel line cut off at first bend approximately one "dose" of fuel?

Q2. Are the injector lines labeled correctly?

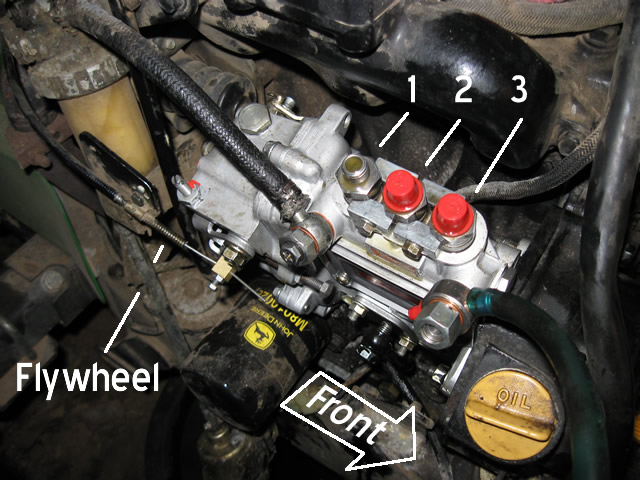

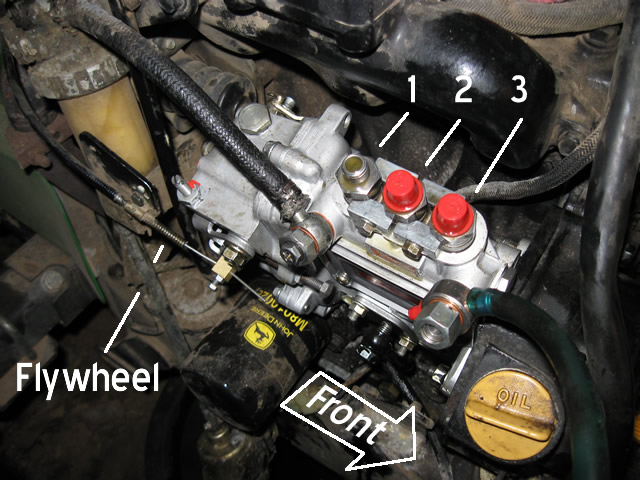

"The number one injector is toward the flywheel." I had thought the number one injector was closest to the radiator, but the 855 flywheel is at the "back" of the motor. See photo below.

Q3. Turn flywheel counterclockwise from driver/operator seat point of view?

The manual says to "turn flywheel clockwise(as viewed from the flywheel end). I've been turning the fan clockwise. It's the only way the BTDC marks show up before TDc.

The spec for the 855/3TN75 is 16 deg. BTDC. The manual illustrates the timing marks behind a rubber plug in the flywheel housing. My 855 has no such housing. I found TDC by observing the piston rise and fall. At TDC the TDC mark on the flywheel lined up with the cutout shown in the picture below.

Q5. Should I try to get another degree closer?

The photo also shows the timing at what I make to be 17 deg. BTDC. Whithin the 1 deg spec. However, there is no fine adjustment left to advance the timing. When I look for index marks on the drive gear I find a "b" only 4 teeth away from an "a" on the drive gear. The manual doesn't mention these marks,

Q1. Is the timing set at the beginning of the injection cycle or the end?

First is confusion over whether the timing mark is set by start of the injection or at the end. The CTM calls for a Timing tool "No 1 fuel injection line cut off at first bend." Later the manual asks to observe when the "tip of the timing tool becomes MOIST [sic] with solid fuel."

I'm not cutting off my fuel line, so I've been doing this by observing the smallest change in the number 1 injector. However, I've also read about doing the timing using the "Spill Cut Off Point" method which waits till the pump cycle is finished. Is this the purpose of the Timing Tool? That is, is the fuel line cut off at first bend approximately one "dose" of fuel?

Q2. Are the injector lines labeled correctly?

"The number one injector is toward the flywheel." I had thought the number one injector was closest to the radiator, but the 855 flywheel is at the "back" of the motor. See photo below.

Q3. Turn flywheel counterclockwise from driver/operator seat point of view?

The manual says to "turn flywheel clockwise(as viewed from the flywheel end). I've been turning the fan clockwise. It's the only way the BTDC marks show up before TDc.

The spec for the 855/3TN75 is 16 deg. BTDC. The manual illustrates the timing marks behind a rubber plug in the flywheel housing. My 855 has no such housing. I found TDC by observing the piston rise and fall. At TDC the TDC mark on the flywheel lined up with the cutout shown in the picture below.

Q5. Should I try to get another degree closer?

The photo also shows the timing at what I make to be 17 deg. BTDC. Whithin the 1 deg spec. However, there is no fine adjustment left to advance the timing. When I look for index marks on the drive gear I find a "b" only 4 teeth away from an "a" on the drive gear. The manual doesn't mention these marks,