Just wanted to thank LotsofGreenGrass for this thread as I just completed a successful repair of my K46 tranny out of a Craftsman DYS4500 which is about 5 years old (not sure how many hours are on it but it has to be getting up there). I probably wouldn't have attempted the repair myself without all the info found here, thanks again!

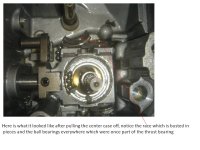

Everything started when my wife was using the mower at her mother's house. She had just completed mowing the back yard and stopped to talk with her mother for a minute before moving to the front. From what she told me, there was a load bang followed by white smoke and then the mower wouldn't move anymore. She said there was just a lot of clanking when it was put into gear and the engine ran just fine. I assumed it was just a drive belt (from her report of white smoke, I mean what else produces white smoke?) After further inspection, the belt was fine and I began to think I had a much deeper problem. After dropping the deck and getting the tranny off, I pulled the pan off and discovered ball bearings, lots of metal shavings and plastic pieces all over inside the case. WTF???

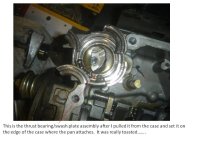

I decided to do some research on this before venturing further which is how I got to this website and thread. I was able to get the parts diagram from the Tuff-Torq website which identified the problem parts as the thrust bearing/swash plate, which was completely destroyed and in pieces. What is wierd is that there was no indication of probable failure before this thing decided to "explode" in the case and I wasn't experiencing the drop in power like others have complained of with the K46.

Nevertheless, I ordered the thrust bearing and swash plate kit from Tuff-Torq (I opted out of getting the Pump and Motor as I really didn't notice a loss in power). I also got some RTV sealant for the pan and 5W-50 synthetic oil locally.

I removed the rest of the assemblies and cleaned out the inner case thoroughly to remove the metal shavings, ball bearings, etc. Re-assembly was easy with the parts assembly diagram from Tuff-Torq (you have to create an account on their website to get these and other items from the website) and the other comments from this thread as what to watch out for. I waited 12 hours for the RTV to dry, filled with the oil, mounted back on the tractor and attached linkages/belts. She didn't do anything at first, until I completed the air purging procedure from Tuff-Torq's website, wow that scared me for a bit!! After purging the air, she just took off and the wheels started spinning!!!! YES!!!!

While the deck was off, I decided to clean it a bit and sharpen the blades with my side grinder as they were looking pretty rough. I'm glad I took the time to do this then as it is a pain to get the blades off otherwise. Anyway, I got the deck mounted and linkages attached, then preceded to mow my lawn for the next 2 hours. She ran even better than before in my opinion, perhaps just having the different oil in it made it better, plus the braking seemed better, not sure why though?

Overall I had about 80 bucks into it with parts, shipping, RTV and synthetic oil, plus a lot of personal time (there was some beer drinking mixed in that time as well) put into this. Much better that having somebody else fix it for hundreds of dollars!!

Thanks again LotsofGreenGrass!!

Brandon Dobler

Little Falls, MN