Richard

Elite Member

- Joined

- Apr 6, 2000

- Messages

- 4,822

- Location

- Knoxville, TN

- Tractor

- International 1066 Full sized JCB Loader/Backhoe and a John Deere 430 to mow with

I'm sure I'm not using the right name.

My backhoe has two wobble sticks. Each stick works north/south & east/west as I'm sure most know.

Two of my boom cylinders have been rebuilt. The small bucket cylinder and the middle dipperstick cylinder.

Both of these were done by my local JCB dealer so I'm presuming they were done correctly.

My bucket will drift/sag pretty quickly. The dipperstick will sag, but not as quick. The boom (the largest cylinder) will also sag a bit.

I'm speculating that since the two cylinders are repacked, the problem is in the controls. (no external leaks).

I'm not yet doing anything but living with this. Right now I'm just trying to educate myself a bit. Especially since I was quoted a price for $400 on one of these parts.

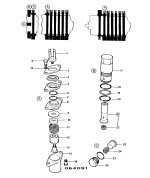

Here's my question. I've attached a TIF to this to show the diagram that JCB sent to me. I don't know all the names of parts. I was thinking there would be a tapered valve in there that would be the main control of flow AND the main stopper.

If I'm right then this is part # 21 (or so I think)

What I'm wondering is, if my unit is sagging, which of these would be the first one to inspect the closest?

My philosophy would be to take the valve apart and replace anything that's worn. Actually, I was thinking I'd simply replace ALL the valves since this machine is from 1987 or so and as far as I know, this is the original valve pack.

Would this have EIGHT of these valves? (part #21) one for each position of the wobble stick?

This is the part that I was quoted $400.... and if there are eight of them, I'm beginning to think I can live with QUITE a bit of sagging before I just go replace eight of them for $3,200

That seems awfully proud. I've not yet called them to see if that was a typo but even at $40 each... that's kinda proud. Not peacock proud but still...

Then there is part #23 "Valve Check Load Hold" Is THIS the part that could be letting it sag since it might not be checking the load??

Again, if I decide to dig into this I'll fix anything that is worn so it's not really a concern which part is which... I'm just trying to get an idea of what does what.

If that pricing is accurate though, then I'll probably not fool with this. I might see if I can get some from a boneyard first.

My backhoe has two wobble sticks. Each stick works north/south & east/west as I'm sure most know.

Two of my boom cylinders have been rebuilt. The small bucket cylinder and the middle dipperstick cylinder.

Both of these were done by my local JCB dealer so I'm presuming they were done correctly.

My bucket will drift/sag pretty quickly. The dipperstick will sag, but not as quick. The boom (the largest cylinder) will also sag a bit.

I'm speculating that since the two cylinders are repacked, the problem is in the controls. (no external leaks).

I'm not yet doing anything but living with this. Right now I'm just trying to educate myself a bit. Especially since I was quoted a price for $400 on one of these parts.

Here's my question. I've attached a TIF to this to show the diagram that JCB sent to me. I don't know all the names of parts. I was thinking there would be a tapered valve in there that would be the main control of flow AND the main stopper.

If I'm right then this is part # 21 (or so I think)

What I'm wondering is, if my unit is sagging, which of these would be the first one to inspect the closest?

My philosophy would be to take the valve apart and replace anything that's worn. Actually, I was thinking I'd simply replace ALL the valves since this machine is from 1987 or so and as far as I know, this is the original valve pack.

Would this have EIGHT of these valves? (part #21) one for each position of the wobble stick?

This is the part that I was quoted $400.... and if there are eight of them, I'm beginning to think I can live with QUITE a bit of sagging before I just go replace eight of them for $3,200

That seems awfully proud. I've not yet called them to see if that was a typo but even at $40 each... that's kinda proud. Not peacock proud but still...

Then there is part #23 "Valve Check Load Hold" Is THIS the part that could be letting it sag since it might not be checking the load??

Again, if I decide to dig into this I'll fix anything that is worn so it's not really a concern which part is which... I'm just trying to get an idea of what does what.

If that pricing is accurate though, then I'll probably not fool with this. I might see if I can get some from a boneyard first.