SilverLakeFab

Bronze Member

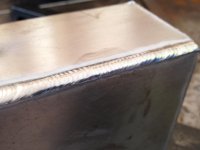

I purchased a Honda RT5000 4x4 subcompact tractor a couple months ago and I was told it had a seized engine. I finally got to start the tear-down last night and I figured I would share the project with the folks here. I've attached a few pictures of the machine to show where I am right now. So far, the front body panels have been removed, the clutch has been removed, a bunch of parts have been unbolted from the engine, and the rubber engine mounts have been unbolted. All that's left is to unbolt the engine from the drive-shaft to remove it from the engine. Where I quit last night was fighting the motor at this stage. It was late and the U-Joint splines are stuck together, so I unbolted the U-joint adapter from the flywheel, but since there's a screen attached to that in the motor cowling, I have to unbolt the cowling the hard way (all the bolts go in from the back side).

As mentioned above, I was told that this engine had a seized engine, but I pulled the head off (yay simple push rod engines) and the piston wasn't stuck (I was able to push in further into the cylinder by hand). However, the piston is no longer attached to the crankshaft either. Who wants to guess how many pieces the connecting rod will be in when I get the side cover off the motor? I'm guessing 5. Even with a catastrophic failure like this one, I should be able to rebuild this whole engine for about $140. Not bad!

I'll post more pictures and info on this little project as I go on with it.

As mentioned above, I was told that this engine had a seized engine, but I pulled the head off (yay simple push rod engines) and the piston wasn't stuck (I was able to push in further into the cylinder by hand). However, the piston is no longer attached to the crankshaft either. Who wants to guess how many pieces the connecting rod will be in when I get the side cover off the motor? I'm guessing 5. Even with a catastrophic failure like this one, I should be able to rebuild this whole engine for about $140. Not bad!

I'll post more pictures and info on this little project as I go on with it.