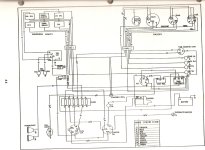

Attached is a wiring diagram for a 2360 that I worked on this past summer for a friend. Looking at tractordata.com, this diagram maybe the same/close for your tractor. The diagram shows three wires coming out of the sending unit 2 black and one brown. I would say the two black wires are ground. One ground the unit to the frame and the other running to the fuel gauge.

With the key just in the on position (tractor not running) touch the brown wire and the black running to the fuel gauge. The gauge should either go to full or to empty. As stated already the fuel sender is a variable resistor. Using an ohm meter and moving the float up and down the resistance will increase and decrease.

NO power should be running to the sending unit.

With the key just in the on position (tractor not running) touch the brown wire and the black running to the fuel gauge. The gauge should either go to full or to empty. As stated already the fuel sender is a variable resistor. Using an ohm meter and moving the float up and down the resistance will increase and decrease.

NO power should be running to the sending unit.