Trails End

Gold Member

I'm in the process of installing the control linkeages for engaging

and disengaging the mid pto, which involves moving the spacer

shown in photo #2 from it's present location to the end where the

snap ring is. Apparently, when the dealer installed the single

rear hydraulic auxilliary kit, they opted to install the spacer

in it's present location, instead of where Bobcat intended it to

go. The Bobcat rear auxilliary kits (single or double) utilize the

same shaft, adding the spacer when only the single auxilliary

kit is installed. If the spacer had been installed just behind the

snap ring, as depicted in the Bobcat instructions, I wouldn't have

to remove the shaft at all. Photo #1 shows the area where the

rear auxilliary control is. Photo #2 shows the spacer and the location

of the snap ring that must be removed to relocate the spacer.

The head of the shaft has to be against the bracket to make room

for the shaft extension for the mid pto control lever. Photo #3

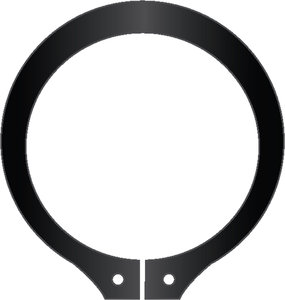

shows the snap ring as viewed from the rear of the tractor (more

than an arm's length away).

I haven't been able to get a grip on the snap ring using the

snap ring pliers, since I can't see the hole locations of the

pin holes in the snap ring. I even tried using a mirror but

my hand-eye coordination just wasn't good enough to make

that work. By the way, the tractor is a Bobcat CT335 HST.:banghead::banghead:

Any tips or suggestions on how to approach this problem?

The only access I seem to have is from the top as shown

in Photo #1. The retaining ring pliers have the 90 degree

.047 dia. pins.

and disengaging the mid pto, which involves moving the spacer

shown in photo #2 from it's present location to the end where the

snap ring is. Apparently, when the dealer installed the single

rear hydraulic auxilliary kit, they opted to install the spacer

in it's present location, instead of where Bobcat intended it to

go. The Bobcat rear auxilliary kits (single or double) utilize the

same shaft, adding the spacer when only the single auxilliary

kit is installed. If the spacer had been installed just behind the

snap ring, as depicted in the Bobcat instructions, I wouldn't have

to remove the shaft at all. Photo #1 shows the area where the

rear auxilliary control is. Photo #2 shows the spacer and the location

of the snap ring that must be removed to relocate the spacer.

The head of the shaft has to be against the bracket to make room

for the shaft extension for the mid pto control lever. Photo #3

shows the snap ring as viewed from the rear of the tractor (more

than an arm's length away).

I haven't been able to get a grip on the snap ring using the

snap ring pliers, since I can't see the hole locations of the

pin holes in the snap ring. I even tried using a mirror but

my hand-eye coordination just wasn't good enough to make

that work. By the way, the tractor is a Bobcat CT335 HST.:banghead::banghead:

Any tips or suggestions on how to approach this problem?

The only access I seem to have is from the top as shown

in Photo #1. The retaining ring pliers have the 90 degree

.047 dia. pins.