Benny Blue

Bronze Member

I posted this (similar post) in the Montana specific fourm as well.....hoping for help here.

I have a Montana R3644 with a FEL, bucket, quick-attach snowblade, harrows and a 5' Razorback bush cutter.

It has been running great. Used it lots for moving snow last winter (and soon enough, again), pounding in fence posts (borrowed neighbors post pounder) and recently, clearing some brush.....

This weekend I was running the bush cutter. Mostly 1" or so brush, and ended up driving it over some chunks of wood (somewhat rotten logs) that were too big..... (hanging my head, yeah, i know a bush cutter is not meant for busting up logs, rotten or not) and the mower stopped spinning. Switched the PTO off, looked for broken shear bolts, didn't find any, turned the PTO switch back on and i could hear something turning, but the exposed shaft was not moving...

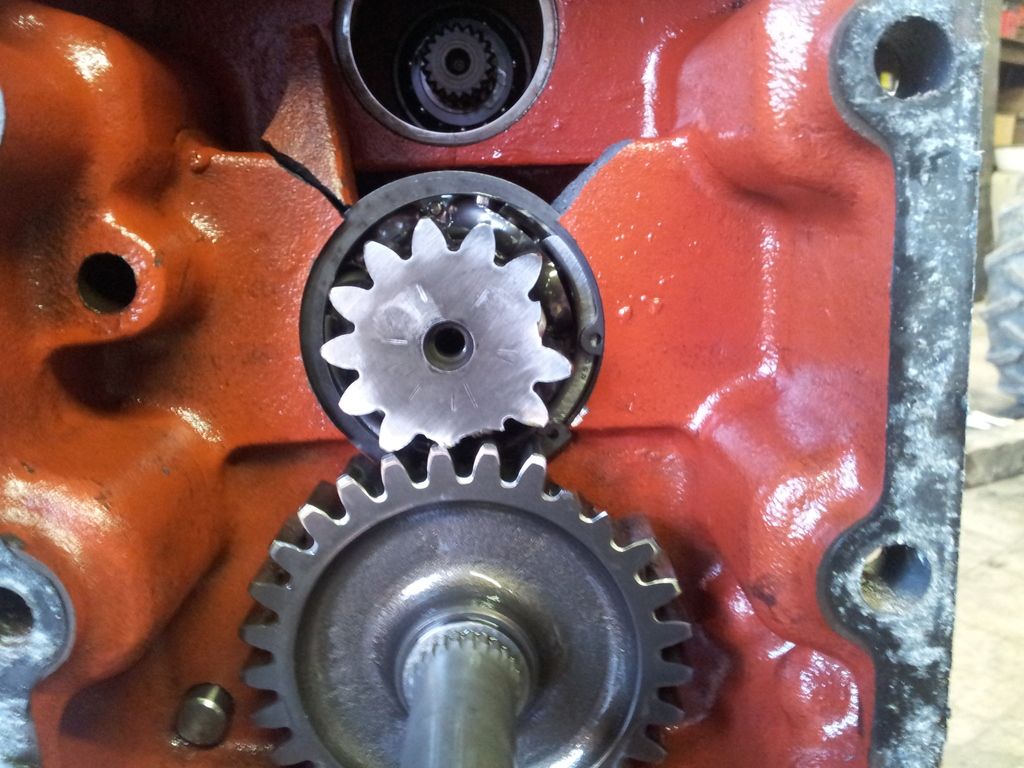

I ended up pulling off the 4 bolts that hold the PTO shaft in place and pulling out the PTO. The shaft that pulls out is roughly 10" long, the splines on the inside of the shaft seemed unharmed, but when i looked inside the hole, i can see another shaft about 4-5" above where the PTO shaft would be and the splines on it were obviously damaged/sheared off. (see attached pic).

I found, fishing thru the gear oil in the PTO gear box with a magnet, a gear that would have pulled off the PTO shaft when I pulled it out. So it sits on the inside of the PTO shaft and engages the shaft that i can see 4-5" above. It had some damaged teeth on it as well.

I'm realizing that this is going to require pulling the whole back end off the tractor to fix.

Has anyone dealt with this repair before? Any Montana service mechanics out there???

I am considering tackling this repair myself and am getting prepped as much as possible. I have a very helpful brother and neighbor who are both heavy duty mechanics and I consider myself relatively capable of handling this with their guidance and i'm hoping for some guidance from the World Wide Web (thats YOU guys!!!! )

The biggest deterrent regarding doing it myself or not is the time the job will take and what can i learn in the meantime about the complexity of doing it.

Any constructive feedback is appreciated.

I have a Montana R3644 with a FEL, bucket, quick-attach snowblade, harrows and a 5' Razorback bush cutter.

It has been running great. Used it lots for moving snow last winter (and soon enough, again), pounding in fence posts (borrowed neighbors post pounder) and recently, clearing some brush.....

This weekend I was running the bush cutter. Mostly 1" or so brush, and ended up driving it over some chunks of wood (somewhat rotten logs) that were too big..... (hanging my head, yeah, i know a bush cutter is not meant for busting up logs, rotten or not) and the mower stopped spinning. Switched the PTO off, looked for broken shear bolts, didn't find any, turned the PTO switch back on and i could hear something turning, but the exposed shaft was not moving...

I ended up pulling off the 4 bolts that hold the PTO shaft in place and pulling out the PTO. The shaft that pulls out is roughly 10" long, the splines on the inside of the shaft seemed unharmed, but when i looked inside the hole, i can see another shaft about 4-5" above where the PTO shaft would be and the splines on it were obviously damaged/sheared off. (see attached pic).

I found, fishing thru the gear oil in the PTO gear box with a magnet, a gear that would have pulled off the PTO shaft when I pulled it out. So it sits on the inside of the PTO shaft and engages the shaft that i can see 4-5" above. It had some damaged teeth on it as well.

I'm realizing that this is going to require pulling the whole back end off the tractor to fix.

Has anyone dealt with this repair before? Any Montana service mechanics out there???

I am considering tackling this repair myself and am getting prepped as much as possible. I have a very helpful brother and neighbor who are both heavy duty mechanics and I consider myself relatively capable of handling this with their guidance and i'm hoping for some guidance from the World Wide Web (thats YOU guys!!!! )

The biggest deterrent regarding doing it myself or not is the time the job will take and what can i learn in the meantime about the complexity of doing it.

Any constructive feedback is appreciated.