Your question: What is that big thing? It is the injection pump if I understand you correctly.

You can think of the injection pump as a very specialized hydraulic jack that pumps a small high pressure volume of fuel to the injector where it is sprayed in a fine mist into the cylinder at just the right time in the engine rotation. The pressures are often 15,000 psi or higher so nothing to treat lightly.

A liquid is in-compressible. In other words if you have a tube full of liquid and apply a force to one end of the liquid that force will be immediately transferred through the liquid to the other end of the tube.

Air on the other hand is compressible. An air compressor keeps squeezing more air into its storage tank and the pressure builds up over time. But air is like a spring and does not immediately transfer force like a liquid does. If you have a high pressure steel fuel injector supply line with a tiny bubble of air in it, when the injection pump tries to send a pulse of fuel to the injector the air bubble will just compress and absorb the force in the fuel. The injector relies on the high pressure fuel to force it open allowing fuel into the cylinder. The injection pump is a bit like a distributor on a gas engine which provides a spark at just the right time for each cylinder but in this case rather than providing a spark it provides a pulse of fuel.

Your question: Why did it not bleed? To bleed a fuel injection system on a diesel, things must be done in the correct sequence or you will be unsuccessful.

First you need to bleed the low pressure part of the fuel system which includes the filters and possibly even part of the injection pump. Having an owner's manual for your machine will be a big help as it will provide instructions on bleeding for those times when you run out of fuel or are doing maintenance. The final step in the bleeding process involves loosening the steel lines at each injector as the engine turns over. Once you get a tiny spurt of fuel out of the slightly fitting tighten it and move to the next injector. You cannot do all injectors at once.

Your question: Why did it stop fuel from making it to the injector? You had not bleed the system in the correct sequence and had air bubbles in the system.

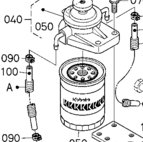

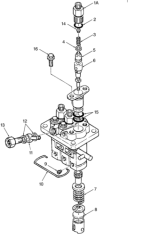

I dont know your particular machine but will point out some things using a photo of a Leyland engine.

The red arrow point to a locking device to prevent the fittings on top of the injection pump from loosening. Most engines have some sort of device to do this job but many are left off or fall off over the years. Making a home made locking device would prevent loosening of the fittings. Keeping in mind the high pressures will help you understand the forces that are trying to loosen the fitting.

The green arrow shows a plastic low pressure hose running between the injectors to bleed off any excess fuel in the injector. It will run back to the low pressure part of the system or the tank.

The yellow arrow shows the steel high pressure line running from the injection pump to each injector.

Hope this is of some help.

Dave M7040