jclaudii

Silver Member

- Joined

- Apr 17, 2012

- Messages

- 135

- Location

- River Valley and South Arkansas

- Tractor

- MF35, Kubota7040, Case885, Ford 1100

I am looking for some help diagnosing some issues with a CASE 885 (david brown) that is extremely slow to turn over and becomes hydrolocked with fuel after a few attempts to start.

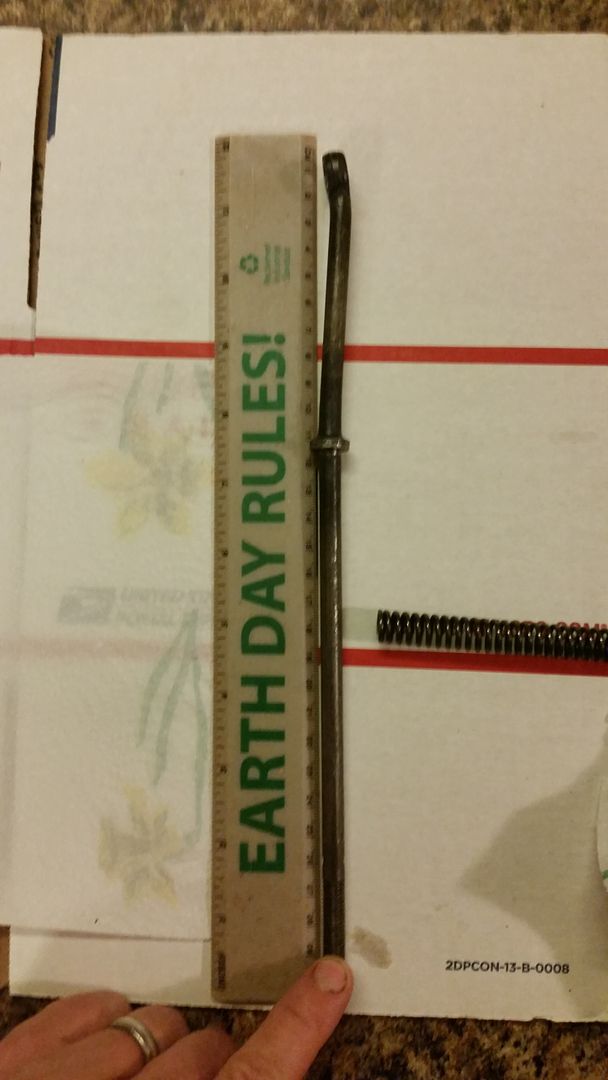

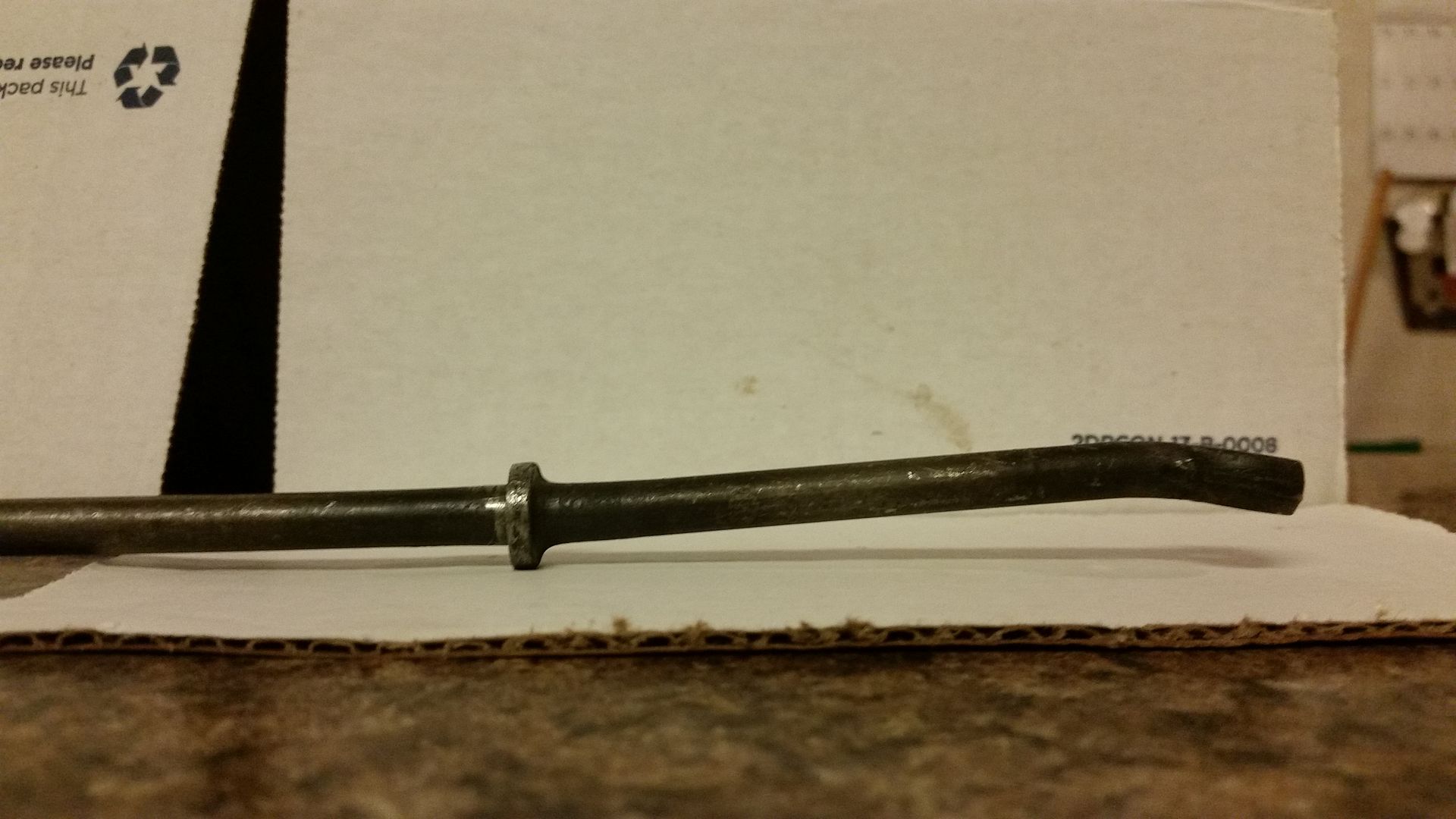

I pulled the injectors out and shot the fuel/water mix out of the cylinders via turning it over and thought that would be good enough. But after getting fresh fuel pumping out of the injector lines, I put it all back together and a a couple dozen revolutions later the starter can not overcome the compression any more, and neither can a wrench on the crank bolt so I'm guessing the fuel has leaked out again and is causing issues.

This tractor has sat for years...i mean YEARS! I'm thinking a brush may be out in the starter causing slow turn over as I melted a set of jumpercables trying to help out my good battery to deliver enough amps to turn over.

Without pulling the head, what is the best way to get that fuel/condensation out?

Oil looks good, got perhaps a half cup of water out of crank case and only about 20-24oz out of hydraulic area.

There are a few froze up controls around the hydraulic area, but hopefully penetrating oil will help with those.

I am completely new to a David Brown style tractor, I am awaiting confirmation to the UK guys David Brown Tractor club forum but thought there may be some help found here. I ran across some info showing it to be a Perkins ad3 / 55a engine...which is similar to my perkins a3.152 in the MF35.

Again, any help in getting this ole girl running again would be appreciated. I really need the bigger tractor to work a 3pt backhoe that my mf35 just can't handle. Thanks in advance for the advice.

jclaudii

I pulled the injectors out and shot the fuel/water mix out of the cylinders via turning it over and thought that would be good enough. But after getting fresh fuel pumping out of the injector lines, I put it all back together and a a couple dozen revolutions later the starter can not overcome the compression any more, and neither can a wrench on the crank bolt so I'm guessing the fuel has leaked out again and is causing issues.

This tractor has sat for years...i mean YEARS! I'm thinking a brush may be out in the starter causing slow turn over as I melted a set of jumpercables trying to help out my good battery to deliver enough amps to turn over.

Without pulling the head, what is the best way to get that fuel/condensation out?

Oil looks good, got perhaps a half cup of water out of crank case and only about 20-24oz out of hydraulic area.

There are a few froze up controls around the hydraulic area, but hopefully penetrating oil will help with those.

I am completely new to a David Brown style tractor, I am awaiting confirmation to the UK guys David Brown Tractor club forum but thought there may be some help found here. I ran across some info showing it to be a Perkins ad3 / 55a engine...which is similar to my perkins a3.152 in the MF35.

Again, any help in getting this ole girl running again would be appreciated. I really need the bigger tractor to work a 3pt backhoe that my mf35 just can't handle. Thanks in advance for the advice.

jclaudii