rsmith02184

Silver Member

- Joined

- Nov 9, 2005

- Messages

- 114

- Tractor

- JD 4100

hi

i have a 2000 JD 4100 compact utility tractor. I use a finish mower most of the time but recently i changed it over to a grader blade.

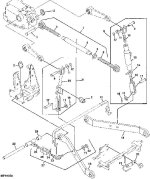

I had to adjust the anti-sway linkage quite a bit to get the 3-point lift arms to fit over the pins on the blade.

During use of the blade, I bent two of the anchor bolts that hold the turnbuckle. These are the anchors that are attached to the bushing on the large pin.

To replace these, it would cost about $150 and I would have to take of the tire, etc. I would rather do something else.

Is there anything out there that can be used in it's place that wouldn't require taking off the tire? Maybe a ratcheting strap or something like that?

thanks

i have a 2000 JD 4100 compact utility tractor. I use a finish mower most of the time but recently i changed it over to a grader blade.

I had to adjust the anti-sway linkage quite a bit to get the 3-point lift arms to fit over the pins on the blade.

During use of the blade, I bent two of the anchor bolts that hold the turnbuckle. These are the anchors that are attached to the bushing on the large pin.

To replace these, it would cost about $150 and I would have to take of the tire, etc. I would rather do something else.

Is there anything out there that can be used in it's place that wouldn't require taking off the tire? Maybe a ratcheting strap or something like that?

thanks